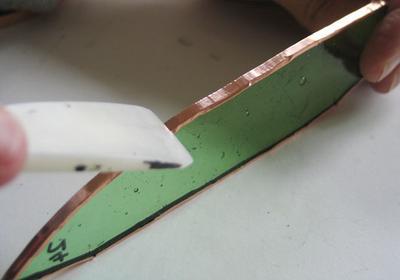

Burnishing foil

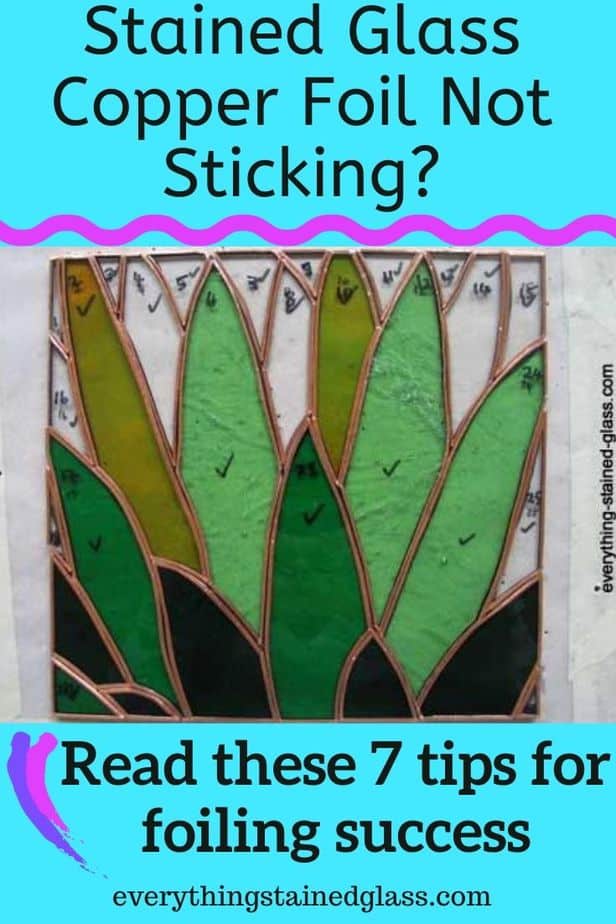

Copper Foil Not Sticking

Copper foil not sticking is a very common problem.There are lots of ideas here to help you overcome it.

If you sometimes find that your copper foil doesn’t stick to the glass or – even more frustratingly – comes unstuck right at the end when you’re polishing your piece – you might find these suggestions helpful:

Milly’s Suggestions About Copper Foil Not Sticking

There are several main problems associated with copper foil not sticking to the glass:

1. The foil sticks better if the glass is warm.

2. The glass must be scrupulously clean and dry.

3. The age of the foil and how it has been kept.

4. Type of foil.

5. Over burnishing.

6. Too much flux.

7. Iron too hot.

Readers Suggestions: Copper Foil not sticking

Kathy Fitzelle :I use Windex or vinegar and water to clean the stained glass before cutting. Dirty glass will dull the cutting wheel more quickly. Then I grind and make sure all edges are ruffed up enough so the foil has something to stick to. Then I towel dry and make sure all edges are rubbed with the towel to remove glass dust and moisture.

I wash my hands before foiling and make sure the foil is burnished enough to see a change in the appearance. It is dull in appearance rather than shiny. It’s important to make sure all edges are securely adhered to the glass so that no flux can get under the foil.I’ve never had any problems using this method.

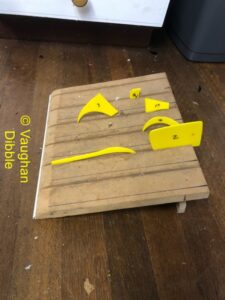

Vaughan Dibble warms his glass with a fan before foiling to help the foil stick. He has made this mdf slope with 4mm grooves in to hold the glass in front of the heat

Soldering iron too hot?

Q: I am having problems with copper foil not sticking too. I have tried two types of foil and 2 brands of flux. It is like the adhesive melts. It seems to stick fine until I add the solder. Then the foil just peels off. Could the soldering iron temperature be the problem? I have one with no temperature control and one with but have had difficulty when I use either.

Milly’s reply:

Yes, either the soldering iron is too hot or you could be soldering too slowly or going over and over the same area too many times.

Copper foil not sticking

A: I have had good luck using a heating pad to keep the glass warm.

Copper Foil Coming Loose

by: Janie

Q: I also am having problems with the copper foil not sticking and coming loose. I have read the comments and wonder if the type of flux has something to do with my problem. I inherited several bottles of gel flux that I have been using but am wondering if I am using too much. I just finished a beautiful Cardinal that keeps falling apart. I need help!

A: You can put too much flux on – particularly on the edges. Gel flux is normally better than liquid. Try using less flux and brush gently along, not across the foil.

Make sure everything is scrupulously clean like Cate says above. Good luck and don’t’ get disheartened!

A: Clean And Clean Again

by: Cate

Thank you for all of your good tips. I have melted the glue, had grease under foil and once you do a redo…you will try to never make that mistake again.

The very first thing I do is make sure I did not miss any edge when I ground the glass.

Wearing rubber gloves I wash my cut pieces in a strong Fells Naphtha soap and hot water bath, Rinse with warm water. Let completely dry

Wearing rubber gloves. I then wipe every edge with a very fine grade of alcohol.

Each piece is then placed in a container in layers on saran wrap

As soon as I am done I begin the foil process or if its not a good time foil, put the lid on the box and set aside.

KEEP all your foil in air tight double baggies

KEEP all of your solder in air tight double baggies.

REDOS are a hazard to your creativity

HAVE FUN…..LEARN FROM MISTAKES but smile as you go ….

A: Copper Foil Not Sticking

by: Paula from Pen Argyl

I too inherited old foil packets that would not stick. I found the inside of those rolls were ok. Unfortunately I had to waste the outer part. Also, if there is too much pressure applied during burnishing the foil will lift off the glass. I have to remind myself to lighten up when I am watching my football team lose on TV or am involved in a tense movie.

A: Copper foil not sticking

Read somewhere that if you wear CLEAN rubber gloves when handling the glass you don’t transfer the oil form your fingers. Might also work with thin latex gloves which would allow a closer feeling of contact with the glass while working. Just a thought – and not yet tried!

A: roll on adhesive

I “inherited” many rolls of copper foil that had completed lost their stickiness. I had some roll on adhesive from another craft project and it was exactly the right width. i rolled it on and the foil worked perfectly.

A: Foil not sticking

by: Delma

I agree with the comment about buying cheap foil to save a little. It cost me more at the end due to copper foil not sticking; foil ripping and wasted time doing it over.

Make sure you not only remove the oil that comes from cutting but also the glass dust from sanding. It acts like a powder and foil will not stick. Good luck.

A: Copper seems to be the worst

by: Karen

Copper does not age well. I suggest never buying more than you can use in three months. Silver and black seems to age better.

Remember teenagers are virtual oil spots. Sometimes a visual lesson to show the oil they transfer helps them remember to clean, clean, clean the glass.

A: Foil not sticking

by: Michael

I feel for all the people having difficulty with copper foil not sticking. I have learned through bitter experience, If you don’t get the basics right it causes so much extra work. I’ve just done quite a large foil project and as a beginner didn’t pay enough attention to the cleanliness of the glass. As a consequence I had numerous pieces of glass to strip out of the project. (soul destroying) When reassembling after washing all the glass the difference was remarkable. I too used a hair dryer to warm the glass. My lesson learned was to wash and dry the glass thoroughly and take care when handling, the slightest smear of grease (difficult to see) causes problems. I too fell into the trap of using too much flux, this stuff will find its way under the edges of the foil if possible, giving the same foil issues. I have used both black and silver backed foil and had sticking problems with both but I shall persevere.

problems with copper foil sticking to glass

by: Shirley

before foiling, be sure to wash each piece with warm soapy water and dry completely. If you do this faithfully, your foil will stick completely, unless there is a problem with the foil. Don’t buy cheap foil from craft stores.

Q: Copper foil problems

I’m also wondering if you can use too much flux? When I was just starting to learn the basics I was told to use lots of flux so that is what I’ve been doing. When trying to find some answers to my problem I read to use a very little bit of flux. I think I will try this as well.

Thank you for replying to my question. I will give your suggestions a try.

A: Hi, yes, I always advise a little bit of flux, and not going over the same area too many times when soldering. That can melt the glue (are you seeing a sticky residue coming out from under the foil? If so, that is the adhesive melting) If you want to go over the soldering more than 2-3 times, wait until it cools before you return to the area. Good luck and don’t give up!!!

Q: Copper Foil comes loose while soldering

I’m having issues with the copper foil not sticking when I’m soldering. I’ve tried wiping the edges with alchol, I bought a new roll of foil, I’ve tried rubbing the foil down more. Nothing seems to help. I just finished a little boy that is fishing to stand in my garden. When I was polishing him to put it outside it fell apart. I was told by the local stained glass store that maybe I was burnishing the edges too much and ruining the adhesive on the foil so I tried not rubbing as much on the fishing guy and he is now in pieces in my shop.

Can you suggest anything I might try. I’ m almost ready to give up on doing stained glass.

A: Hi. I’m really sorry you’re having problems with the foil and are thinking of giving up. Please don’t !!!

Try cleaning in warm soapy water rather than alcohol. Unless the alcohol is the best quality it sometimes makes things worse.

I’m assuming it’s the edges you’re having trouble with? They are always delicate, especially if you have tinned (just covered the foil in solder) rather than creating a beaded edge (a rounded bead of solder that is stronger and holds itself to the edge of the glass).

Also, try polishing them lengthwise, rather than across.

Another thing I’ve noticed a couple of times lately is that the black-backed foil is less sticky than the copper backed. This could be completely random, though!

There are more Questions and Answers about foil not sticking here

For more tutorials about the copper foil technique go here

Return to the Everything Stained Glass Home Page

Sometimes when I rub my fingers along the soldered edge of a finished piece, it feels sharp. Is that a problem in foiling or soldering? Thanks

Good question Nancy, it could be either! If you’ve soldered with your iron on too low a heat you can get little spikes because the solder doesn’t melt enough.

Or sometimes when the foil is joined together or trimmed, there are slithers of foil that stick up and get caught on by the solder and aren’t smooth.

Hope that helps

I have been using a seed mat that plugs in to keep my glass and foil worm while I am building a project. My glass seems to cut easier when warm,the foil sticks better when put on clean,warm glass too. If I can not finnish a piece while foiling, I put everything in a zip lock baggie until I can go back to work on it. 🙂

Sounds as if you’ve got it all sorted Bee 🙂 I know lots of people favour warming the glass. It’s not something I do but I’m happy if it makes cutting easier. Perhaps I SHOULD try it lol.

I am working on my biggest project to date. 25″ x 44″. Glass is cut. Edges ground. Glass has been cleaned but not yet wiped with alcohol. I do not have the time to solder all in one day. Before reading all these tips I would have foiled everything and then just soldered over a few evenings. Now I am thinking I should take a different approach. But I can’t think of any way to not have some edges of foil sit for a day. Any suggestions?

I’d recommend cleaning off the flux as you go. Kwik Clean is handy for this as it doesn’t need water. If you can cover it with polythene or saran wrap that’ll help with the oxidation but if you’re going to do it over the course of a few days (rather than weeks) I wouldn’t stress too much about covering it.

I hope that helps 🙂

Hi You might find thet the foil might be old, and the adhesive has given up the ghost like old masking tape. In this situation its better to try a new or different roll to eliminate this problem, or it may have been stored in damp conditions. you^re welcome

Absolutely spot on Bill, thanks for adding your thoughts.

On a different subject, I’ve just looked up the origin of ‘give up the ghost’:

“To give up the ghost means to expire or die, or in the case of a mechanical object, to stop working. The phrase give up the ghost may be traced back to the King James Bible, printed in the early 1600s.” Fascinating, and very apt when it comes to deceased copper foil 🙂

Does it help to have the foil a little warmer, too?

Good point Marilyn. Some people warm their foil before starting. I live in a temperate zone so don’t need to but it’s a good idea to give it a try if you’re in a freezing zone 🙂

Too much humidity will cause problems with foil sticking. If you luv where there is too much humidity keeping your foil in the refrigerator when not in use,

Thank you for the tip, very helpful 🙂

Thank you so much for the tips! I live in Arizona and have a craft room off of my garage. I have been leaving the foil hanging on a peg board! This may explain why I am having problems with the foil coming up! I will replace it, move it indoors and leave it in a nice plastic bag!

Good to know the tip was useful Chris, thanks for taking the time to comment.

Hello: IM working on a piece 32 x 18 about 200 pieces and the insider corners of the lotus petls the tape has lifted during soldering and the piece is already together what can I do to fix it?

Also if you leave flux on a piece and cant solder right away does that oxidize the copper?? Having issues with flux and solder sticking in small areas. Please help!

Yes, you need to either wash the flux off or solder as soon as possible after cleaning. Immediate is best.

If the foil lifting is in a structural place you’ll have to replace it by melting the solder and removing the piece, including tape, washing and refoiling and soldering.

If it’s not going to impact on the strength of the piece you’ll have to assess how you can disguise it. Try resoldering and flattening the foil or even getting a bit of glue under if it’s only a small bit. Just be careful if you go down the glue route – you don’t want any getting on the glass and making things worse.

Hi Millie,

I need help on a foiling problem that I have not seen mentioned,

I have foiled and tinned several pieces that are now completely oxidized.

What happened and can I fix it or do I have to disassemble and start again.

I clean and scrub each pieece in warn soapy water. The foil generally sticks

okay. I did not know that the copper foil should be stored in a baggie.

Could that be my problem with oxidation? I have also recently heard that you should

solder soon after foiling. My foiled pieces often sit for days (or longer).

Could that also be part of the oxidation problem?

Thank you foe whatever help you can give!

I have a cheap and quick answer on your oxidised copper foil problem for you here Debbie 🙂

Yes, keeping your foiled pieces hanging around will add to oxidation. Solder as soon as possible after foiling. If you can’t get to it, keep it airtight.

Good luck!

Thanks. I never have any problem. When I sit down and think about it, I think soap and water better to clean edges than ammonia or degreaser, but the iPa is good idea, for drying.

Glad to hear you don’t suffer from this Mike 🙂 Thanks for your thoughts – soap and water always good!

Hi! It was very interesting to read each case. It happened to me and I’ve learned the lesson. I was told to keep my copper foil inside air tight double bags IN THE FRIDGE! Os it necessary? Which is the reason it needs cold?

Greetings from Argentina!

I’ve heard the same thing about keeping the copper foil cold Ceci but have never needed to try it myself as the airtight bag does the trick. You don’t want it to get hot though, so maybe the weather in Argentina demands a cool fridge. We don’t have that problem with heat in the UK 🙂 Anyone else put their stained glass copper foil in the fridge?

I think everything has been covered, it could be the humidity on the cold glass, contaminated glass or even a bad or old batch of foil, check and test warm and clean the glass and try new fresh foil…. the first two are the cheapest options … good luck

Thanks for your additional tips Bill, that’s very helpful. It’s certainly a common and very annoying problem.

i have done glass now for about 30 years and hate foiling….my answer to foil problems was to do lead instead (ha, ha, ha). I always use Dawn blue dish soap in hot water. Rub well with sponge or cloth and rinse thoroughly. I stand each piece on end to drain and air-dry. Then I rub each with a high-percent alcohol and hit the edges again. I foil usually sticks just fine if I can keep from burnishing too hard….and my favorite burnisher is a popsickle stick or craft stick. They are hard enough to get the job done and soft enough to not damage the foil. (still like lead better but they don’t make very good suncatchers)

ps …i found tinned wire of gauge 22 or 24 in the bead section at the local variety store (Walmart) and i run it under my solder on all seams that will act to give support to the joint and take some of the stress from each solder run and then finish with one hidden under the solder around the edge in one piece.

This is brilliant information Sherry, thanks so much for sharing it. I like your workaround for not foiling – using lead! The popsicle (lollypop in the UK) stick is inspired 🙂

I a;so use hanging cable multi brain wire for hanging the picture

easy to solder and stronger

Thanks Jacques. I think this may have been lost in translation as I’m not sure what multi brain wire is…

Hiya! I can say with absolute certainty that black backed foil does NOT stick as well. I’ve been working with Stained glass for about 20 years, trust me….it sucks. I don’t know why, I have tried different brands, brand new, old, blessed by the Pope, nothing. I loathe black backed foil. Life is too short! Have a groovy day!

This made me laugh Berkeley! I’ve had similar experiences with black backed foil too but it’s so nice not to see silver or stained glass copper foil in the finished piece…

Thanks for sharing your considerable experience and feel free to add any more tips on my site.

Aw that might be some of some of my problems with foil, not bless by the Pope. No usually its because I didn’t have it in sealed baggie and exposed to air. Now I leave them in plastic bags and store in a plastic she box. Stores easier in the box. I also learned not to allow the foil to stay in my shed during the summer, too hot and ruins the adhesive. thanks for all the tips. 🙂

Milly hello, I see that someone asked about problems with foiling a piece for the garden. Can foil tpieces go in the garden? I was told that you should only use lead cames for stained glass in the garden as the copper foil cannot withstand the weather? I would love to be able to use copper on pieces to go in the garden if this is possible.

Yes you can use copper foil outside. It’s best to bring them inside in really extreme weather but I’ve left stuff outside regardless and it’s been ok. It’s a good idea to give them a good clean and brush up from time to time anyway so that would be a good excuse.

Thanks for your question, I hope that helps.

Just a funny little story about outside glass projects. I made some butterflies using came. The silly squirrels ate the came. I now have some silly brain damaged squirrels running around

This can’t be true!!! Wow, it’s amazing they’re doing so well in the world…

Squirrels eating the lead came doesn’t surprise me at all. My job gets me on a lot of house roofs and I often see chewed up lead plumbing vent pipe flashing boots. I figure that the lead tastes sweet to them or something.

Squirrels? OMG, that won’t do them any good at all. Interesting!

For foiling inside curves it helps to put a small piece of foil across to deepest part of the curve then foil starting inside the curve and overlapping in the curve. The extra foil (across) can be trimmed with an exacto knife. I always grind the glass before foiling an d also wash with glass with warm soapy water. No problems with foil not sticking aft that.

That’s a good idea. Do you mean you stick the small piece of foil in the deepest part of the curve first? I do that if/when it splits but hadn’t thought to do it first. I can see how that might work (it allows for the expansion inside the curve) and I’ll give it a go next time. Thanks for sharing!

I tried to put apiece of foil in the corner but the foil did not stick to the foil that overlapped it. Have you ever had this problem?

I can only think the foil underneath had some grease or flux or something on it Michelle, it should stick to itself.