Cutting and Measuring Queries

Measuring Panels Confusing

I don’t understand something about measuring stained glass panels. If you have a lead window and the lead is say 1/8in. thick and your glass goes into the window that much,less the end thickness which is about a 3/2 of an inch, well, do you have to compensate for drawing, because you will lose some of the glass that will go into the lead. Does that make any sense?

Milly’s reply: Yes your question does make sense – it’s the process that’s a bit confusing! There’s two considerations here; measuring the aperture and the width of the lead.

1. Measuring the aperture. When you measure the size of the window, you must take into account the fact that the beading and rebate of the frame means that you have to make your design a bit smaller than the actual size of the window. Take two measurements, one to the outside edge of the window to get the full size of your stained glass panel – this is known as the ‘tight’ size – and two, measure the inside of the beading/rebate – known as the ‘sight’ size. This ‘sight’ size is the size you work to with regards your design. Have a look at Measuring the Aperture for more detailed information.

2. The width of the stained glass lead. You’re right Bob, you will lose some of your glass under the flange of the lead. The amount you lose will depend on the thickness of the lead, so you have to be mindful of this when you do your design. For example, if you have a shape that goes to a point right at the edge of your panel, you might want to keep the point by moving it slightly away from the edge on your design, so that the outside lead doesn’t chop it off when you lead up your panel.

I hope that answers your question, and good luck – I hate the measuring bit.

What Shall I Use For Marking Glass?

I use a Taurus 3 ring saw for intricate cuts on stained glass. It works beautifully but I can never get my pen marks to stay on the glass long enough to finish my cuts. I end up removing the piece, drying it off and reapplying the pen marks. It’s frustrating and tedious! I have tried Mark Stay with little luck. Do you know of any other techniques that might help keep the pattern marks on the glass long enough to get the cuts done?

Milly’s reply: Have you tried a permanent OHP (overhead projector) pen line covered in vaseline? That normally works for me. You can also use the vaseline over the Mark Stay.

Or what about the BathTub crayons for children? I haven’t tried this, but some grand-parents swear by them. I would condone stealing children’s crayons, though!

Or what about wax crayons? I’m not talking about the type children use for drawing, but the more industrial type used for marking construction surfaces. I’ve seen some on the web, called Paint Crayons, that claim to ‘mark any surface with ease: Rough, oily, wet, hot or cold -50F – 150F (-45C-65c) Crayons made of solidifed paint for use on: metal, wood, concrete, stone, plastic rubber, glass, cardboard, canvas, etc’. Not sure where you’d get them – I’d try Do It Yourself stores first.

If anyone else has any ideas for permanently marking your stain glass patterns on glass for use with water let us know.

Can I cut this shape?

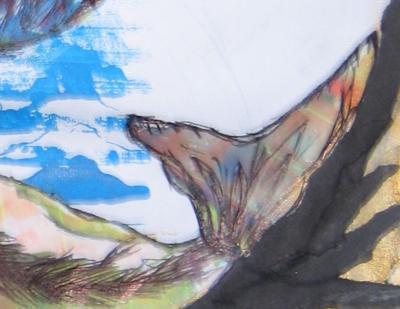

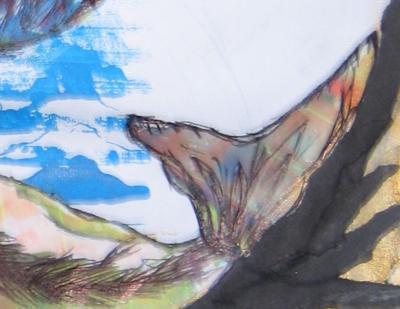

Fish design for glass project

I am making a leaded panel where a piece of glass requires a reasonably deep inward cut (As shown in the picture around the fish tail). Would this make the glass more likely to break and should I modify my design in case this should happen.

Milly’s reply: Nice design! You’re absolutely right, the inward cut will cause the glass to break across. Even if you cut it with a water-jet cutter it would be very weak and likely to crack within a minute, so it’s best to modify your design.

You could gently echo the shapes of the water using a narrow lead – that would limit the visual ‘damage’.

I’d love to see the finished piece – you could upload it onto the site once it’s done for us all to have a look at. Thanks for your question.

How to cut glass accurately?

I am using the foil technique and my glass cutting is just not that accurate. I have small gaps between foiled pieces. Am I being too much of a perfectionist or is there a way for better cutting?

Milly’s answer: Hi Daniel, thanks for your question. Copper foiling does require more accuracy in cutting glass, but there is a point at which you need to stop, otherwise it can drive you crazy!

Are the gaps you talk about big enough for the solder to seep though and ‘disappear’ to the other side? If not, your cutting’s fine. If this is happening, and you can’t ‘fill’ the gap with extra solder, your cutting is probably not accurate enough. You could try looking at my Glass Cutting page, to see if your technique is ok. Are you holding the cutter at right angles to the glass, for example?

Another indispensable part of your stained glass kit for copper foiling is a grinder. It will help you get rid of those annoying nubs of stubborn glass, and in doing so eliminate gaps. If you don’t have one, check out Stained Glass Grinder for buying advice.

Good luck – let me know if the problem persists.

I’ve suffered the same loss of marking and have found that using wax pencil over a sharpie works.

Thanks for this tip Vicki, very helpful.