How To Frame With Stained Glass Zinc Came

Stained Glass Zinc Frame A stained glass zinc came frame is a good option for the edges of your panel. This is for a couple of reasons. If you have a heavier panel that needs … (read more)

In this section you’ll find all the making stained glass tutorials related to the Lead Came Technique. They take you from Choosing Lead Came right through to Cementing and Polishing.

Save time, money and precious glass with this little-known technique called Lead Lining. It will help you get your colour choices spot on right at the beginning and reduce disappointment.

Guarantee your stained glass is strong, weatherproof AND lasts a lifetime by finding out how to cut and shape lead came accurately. With tips on cutting those tricky long, thin angles.

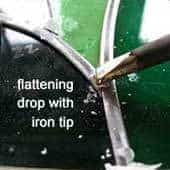

Make sure that your stained glass solder looks professional and tidy with these simple to follow instructions. Includes tricks on filling in gaps and answers the most common soldering problems.

Stained Glass Zinc Frame A stained glass zinc came frame is a good option for the edges of your panel. This is for a couple of reasons. If you have a heavier panel that needs … (read more)

Methods For Repairing Broken Stained Glass Fixing broken stained glass is a necessary evil. With glass as a material breakages are inevitable. You know the scenario; you’re happily soldering away on your latest piece only … (read more)

How To Make Accurate Straight Cuts & Angles Cutting lead came for stained glass isn’t as hard as you might think. To make an accurate cut on both sides of the panel you have to … (read more)

Helping You Choose Stained Glass Colors Stained glass colors are what makes a window ‘sing’. If you get them right your window will hit the high notes. If you get it wrong it will seem … (read more)

Find out about the range of stained glass lead sizes and profiles available, with tips about when best to use them.

Assembling leaded stained glass is a logical process if you know what you’re doing. These answers to common problems will fill in the gaps and make leading up stained glass easier for you. Assembling Leaded … (read more)

Milly’s Free Stained Glass Videos Often we need to see a stained glass technique before we understand how we can improve. Here is a selection of my free stained glass videos so that you can … (read more)

Stained glass lead soldering is FAR easier than soldering copper foil . The main reason for this is that you are only soldering a small area each time rather than along a whole seam. Think … (read more)

Make you stained glass sparkle! Expert stained glass making tutorial on blackening lead came with polish.

Copper Foil vs Hobby Came Explained I am a copper foil guy and have not used lead came before. What are the advantages and disadvantages over copper foil? Milly’s Reply: Great question, thanks Joe. It’s … (read more)

I get a small % from selected suppliers (not you!) if you purchase any shiny new tools after clicking through from my site. Thanks in advance for your support.

AMAZON – As an Amazon Associate I earn from qualifying purchases.