Measuring For A Window

If you want to make stained glass windows that are going to fit into a specific building, it’s important to get the measurements accurate right from the beginning. It’s best to take the measurements even before you start your design, so that you can scale your design up easily to fit.

Do you need to measure?

You only need to take these measurements to get your panel to fit in a building. If you are learning how to make a stained glass sun catcher, or a hanging panel that doesn’t need to fit in a window frame you don’t need to take these measurements. You can go straight to Designing or Finding a Pattern.

1. Measuring The Window Opening

This is quite hard to describe but isn’t hard to do once you break it down logically.

If you think about the task in three stages, it might help. You need:

- the size of the opening – the Tight Size

- the adjustments needed to make room for putty – the Fitting Size

- the measurements needed so that the whole of your design is visible – the Sight Size

Once you’ve done this you can then move on to the final measurement – the Cutline Size – so that your pattern is accurate for cutting. This is worked out in relation to the width of your perimeter lead. I explain this further down the page under Section 3 .

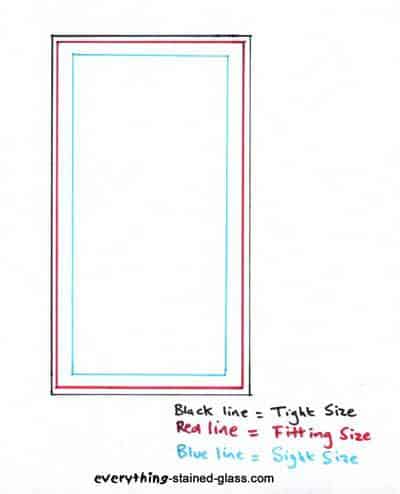

1. the Tight Size = the exact size of the window opening you’re making your panel for.

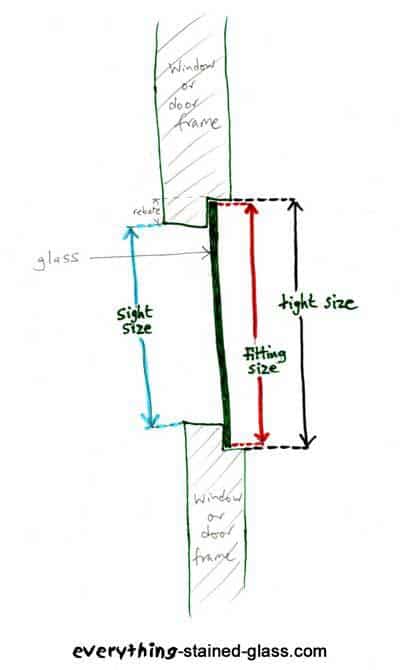

Have a good look at the window or door panel. You can probably see that the sheet glass is held in with either putty or a wooden rebate. The drawing above might help. You need to measure not only the glass you can see, but to the edge of the frame underneath the putty or wooden rebate.

This will be your largest measurement.

2. the Sight Size = the size of the glass area that you can actually see.

If you have beading or putty holding the existing glass in around the edges, measure to the inside edge of the beading. The diagram above explains this. You need to know this measurement so that when you make your panel the whole of your design will be visible.

You wouldn’t want the tip of a leaf to be chopped off behind beading, you want it all to show.

This measurement is your smallest measurement.

Some people call this the Daylight Size.

3. the Fitting Size = the measurements of the outside edge of your stained glass panel.

This is worked out in relation to the Tight Size.

If you imagine going to a glaziers and asking them to cut you a piece of glass for a window, they never cut the exact, (tight) size of the opening, they always take a bit off around the edge so that there is some ‘wiggle’ room and for the putty to fit in around it.

Work out the Fitting Size by subtracting 1/8th inch or 2mm from each edge of the Tight Size. The drawing above might help you visualise what I’m talking about.

This set of measurements will be somewhere in between the Tight and Sight Size.

Once you’ve got your fitting size measurement, you can forget about the tight size altogether.

2. Things to Remember

- Make sure you measure all 4 sides. Some windows are not geometric!

- If you are making a pair of windows, measure both. Never assume windows are the same size, especially in older buildings.

- Measure the angles to make sure the window is square. Templates can be used for very irregular shaped windows.

3. Taking The Final Measurement – Cutline

Once you’re happy with your coloured design (sometimes called a Full Size Cartoon) you need to make a Cutline for cutting the art glass pieces accurately from it. You might call this a pattern.

Traditionally the stained glass artisan would work up a full size cartoon which included all the colours, lead lines and decorative detail needed for the window. This gave them a chance to see the balance of the finished window before committing to glass.

Then a thick sheet of tracing paper would be laid over the whole cartoon (design) and the Cutline traced on it. The lines were traced down the centre of the lead lines.

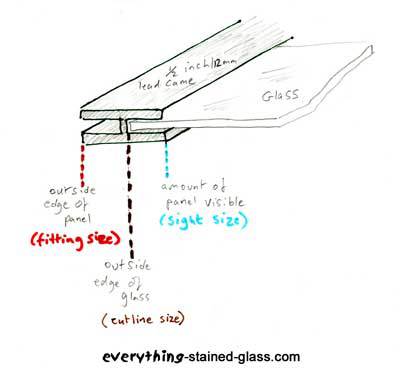

the Cutline = the line pattern you work from to cut your glass. This measurement has to take into account the width of your perimeter lead or zinc.

If you look at the drawing below, you’ll see what I mean.

You can see from this diagram that you can’t use your Fitting size for cutting glass, otherwise there will be no room for the lead or zinc came, and your panel will end up too big. So you must cut your glass smaller to allow for the border lead or zinc.

How much smaller depends on how wide your border lead is. Let’s use the example of 1/2inch (12mm) lead. This is the width that is usually used to edge window panels.

You want to cut your glass to the inside of the heart, so you need to measure 1/4 inch (7mm) in from each edge of the Fitting size for your art glass cutting pattern (Cutline).

This Cutline will be in between your Fitting and Sight size.

Check Your Measurements

It seems very complicated when I explain it, but if you take it a step at a time, you’ll see that it’s quite logical and obvious. I always get all these measurements worked out – and checked three times! – at the beginning of a project. I write them all down in my sketchbook clearly, making sure I label them.

Once you’re happy with them, and are confident they’re accurate, you’re ready for Designing or Finding a Pattern.

Learn the Lead Came Technique

Learning lead doesn’t need that many more tools and is a LOT easier than you think. And so satisfying!

If you haven’t tried using lead yet and would like to learn how to make windows to install in buildings but don’t have a local class my online Leaded Stained Glass Artistry course has taught many people – even those who have never used lead before – how to make a stained glass panel using lead came.

The course is self-paced and online so you can learn this lovely technique even if you are unable to get to a class. You can find out more about it here Leaded Stained Glass Artistry

Using Zinc? This page on U came has some detail

Hello Milly

I have followed your posts for a while now and the videos are just great, really clear and helpful.

My question though, is concerning a circular panel I’m making for a round window. It will be fixed in place, made in Tiffany style and is 50cm diameter. I am confused about which came is best to use for this, apart from lead rather than unbending copper or zinc! Could you point me in the right direction please?

Yes, I’d go for 1/2″ (12mm) H profile flat lead. This will give you some fitting flexibility as you can trim the flanges of the lead if your circle is a tiny bit off and doesn’t fit perfectly. Good luck.

Hello Milly, I made a 70″ panel over my couch. I did not butt it up next to the existing window because it is a split window. So I mounted it about 5″ away, flush with the sheetrock. It has worked out, but has no direct sunlight. I recently made another 70″ panel for my dining room window. It however does have direct sunlight (mostly morning, by noon it’s gone). I also mounted it 5″ from the split window. My window feels cool but the panel feel warm. Is this ok? I just don’t want my panel to break because of the heat. I appreciate any tips you could give me about this. Thank you, God bless.

It should be fine Cynthia, unless your particular set up encourages an abnormal build-up of heat.. There are stained glass panels all over the world that have been exposed to the elements for years.

Hi Milly

I too have a sight size smaller than the fitting size. I want to see some lead border, so how much lead should be visible? Should the edge of the glass be ‘Seen’ or should it be a mm or two behind the moulding? I realise I’ll have to pack underneath/around the panel so it fits.

It depends on the width of the lead Liz, you want to have enough lead behind the frame to be stable. 2-3mm gives a nice slim outline around the edge. Good luck.

Thanks Milly 😊

to measure an opening i like to use “try Sticks” using flat wood sticks. cut a piece slightly longer than the opening. set it in a corner against an edge. mark the end @ 1/8 or more smaller “wiggle room” . move it across the opening making sure it is a nice fit all across the opening. label stick, then repeat process on the other dimension. what i like is I don’t need any numbers, just the 2 sticks. back in the studio I lay out the window board using the sticks to measure stops on the board . nail up 4 sides for foil, or three for a lead window. you will of course have to allow for came and borders, but if your sticks fit you know your panel will fit.

Ingenious Geoff. The thought of no numbers is extremely attractive to me – I have that number blindness thing! thanks so much for your detailed explanation. I’m going to try it next time.

Millie,

As always you give us so much! Most of what I do is self taught, trial and error. I always have three lines on the edges of my panel pieces and thought it was something I made up because I wasn’t so good at getting things together. This article validates me! I’m very appreciative. Also, if I am using a wood frame I will have a 4th line for it’s edge as well.

Thank you.

Great stuff Wanda, you worked it out for yourself. I think I might call that line the ‘Sight Size’ but I’m not entirely sure which one you’re referring too. Measurements drive me crazy LOL.

Love your newsletter and the tips and advice you provide. Very useful and helpful. What is the best way to copper foil small glass beads? They are about 0.5 to 0.75 inches in diameter and not perfectly round.

You can foil around them and then shake them together in a plastic cup or similar. They burnish themselves, it’s a miracle 🙂

Though I’ve only worked with the “foil” method of making stained glass, I know using your lessons on how to do lead would get me through any lead project I ever decided to do. Your knowledge of everything stained glass is second to none. You explain things so clearly! Thanks for all you do.

Thanks for your vote of confidence in my teaching Gail, I appreciate it 🙂

Hi Just wondering if you can advise on measuring for a half moon semi-circle window. I measure the width and the height (at tallest point). If it’s symmetrical the height should be half the size of the width. Is it that straightfoward? Would you assume that most semi-circle window apertures are more or less symmetrical? Any other tips for this shape. Thanks so much

I’d never assume anything with windows, whatever shape Siobhan 🙂 The very best foolproof method is to make a template. Thanks for your very good question.

Hi Milly, I am also needing to know this, as the window I am replacing has a semi circle as the top of a rectangle, if that makes sense! I also need to replace an oval.

What is the best way to make a template when the existing window is in situ?

Thank you : )

You can use thin white paper (like very heavy tissue paper) initially. It’s easy to manipulate taped against the windowpane, then trace and cut as needed to fit. I always mark which direction is which before removing, and make a more rigid version with cardboard from that to make a final check.

I hope that helps Sam.

I am making 26″ x 33″ window panels with 9 panes that are

8″ x 11″ each using 1/2′ flat came. The panels will be in a wooden frame on an outside porch. Should I cement /putty both sides of window panels? Thanks

Yes, putty both sides Don. It’s actually hard NOT to putty both sides as it seeps through. It will make it much more rigid and stable.

Good question, thanks for asking.

Thanks for this helpful guide to measuring -something I’m not great at! I am designing two panels for my bathroom door and have a few questions I wonder if you can help me with..

The panels are each 100.5cm x 24.5cm. I have designed the pattern as pictorial with a lighthouse on one side, sea cliffs and rocks on both which has been a challenge!

My questions are do you think it will be strong enough as a door panel if I do it completely with copper foil without lead/zinc round the panels? I think it too narrow to do the project in lead and am happier working with copper foil.

How many pieces right across would I need to strengthen it. I have strengthening “tape”

When setting it in to the space do you have a sealant you’d recommend which I presume would strengthen it as well as stop movement. I had thought of placing a sheet of clear glass under it but would prefer the panel on it’s own.

I’d be grateful for your advice if you have time.

Many thanks Liz.

Sounds a great project Liz. I’d always put lead/zinc around the edge for any panel of any size, for stability. This is especially important in a moving panel, like a door. You can do the window itself in foil. Use ReStrip (or similar) every 12″ or so, design dependent. You can putty them in or silicone in.

I hope that helps, good luck and send a photo when you’re done!

I have a question about sizing for a glass window pane that is 11.5 inches. I don’t plan to enclose the window pane glass in zinc or lead just use silicone to hold the glass pane in the window frame. So, would I stop at the fitting size measurement (taking an 1/8 inch from each side) or what do you suggest.

Thanks,

Diane

Spot on Diane, yes. The fitting size is what you need. Good luck 🙂

Hi Milly thanks for your great site. I am confused about the different sizes of outside lead and inside lead. I know the outside border for my project is 12mm 1/2 flat and glass size is 3mm. The only inside lead size I can find is 8mm 5/16 flat. Would this be right for the size of glass?

Many thanks Fiona

It IS confusing Fiona! The height of the came fits most standard glass thickness – 3-4mm. The width of the lead for internal work is normally 5 or 6mm. 8mm would be a bit wide for general use but good for emphasising a certain area or shape.

This page on lead sizes will help you further: https://everythingstainedglass.com/stained-glass-lead

Hello ! Great site.

I’m a bit confused with the fit of lead came and glass. I’m making a terrarium, using came with a 5mm channel (the smallest I could find) and 2mm thick glass.

I understand that the black putty will take up some slack, but unsure if the glass is too thin.

Is this likely to be a problem ?

Many thanks

Ron

Hello Ron, 2mm glass is picture framing glass so it is thinner than normal (3mm). It will leave more room in the channel which you can fill with cement so it shouldn’t be a problem per se. However, it won’t be as robust as 3mm glass so if you have some fairly large pieces I’d go with 3mm.

The terrariums I’ve made have been using the foil method as I find it easier for 3D objects.

Glad you like my site, thanks 🙂

Thanks Milly

Hi Milly, thankyou so very much for responding to my question about how to measure pattern for a specific size and accommodating the zinc. Was super helpful!! Love your site. Have been making glass for 40 years and still learning!!! Thanks so much

Oh great, thank you for telling me Diana, that’s made my day 🙂

Hi Milly,

Have you used the Gemini Taurus 3 saw? If so, what do you use for your pattern material? Mylar, cardstock? Any information will be helpful.

Yes I do use these saws for certain cuts Karyn. I use permanent pen with vaseline over to guide the cutting. I hope that helps.

Im building a 18”x 90” window and dividing it into 3-18” x 30” panels. Two questions: what size U zinc would you use to frame it and what size lead to build it?

1/2″ zinc or lead came for the edging.

The internal lead came size is up to you and depends on what you want to emphasise and your design. You can use a variety of widths for this. Anything above 5/16″ / 8mm is a bit heavy on the eye and hard to manipulate so I wouldn’t advise any wider than that.

I hope that helps.

Hi, I’m making panels to go above the opening/doorway between my lounge and dining area. . Do I still need to use thick came at the edges or could I use the finer came that I will use throughout the piece? Not sure if it’s just a personal coice thing, or a structural need.

I’ve had a 10 year break from this. Feeling nervous about measuring up. This has been so useful . Thank you so much.

Judith

I would use the wide lead came, yes. It gives you room for a little bit of leeway with your measuring and fitting, as you can shave the H came to fit when you install. Usually the came is covered by beading/quarter rounds, so you don’t see it.

That sounds like an exciting project Judith. I hope that answers your question.

Thank you for suggesting that you need to make sure and measure all four sides of the window. My husband and I are wanting to get a stained glass window for our kitchen. I’ll have to look into finding the best company to make and install this for us.

You’re welcome Ellie. Most windows are accurate but there’s always one that catches you unawares if you don’t measure!

Milly: your website is very informative and clearly stated. I have been away from stained glass for 20 years but anxious to get back at it. I would like your recommendation for puttying a finished piece. Have looked at recipes for mixing putty but would prefer using ready mix. Do you have a recommendation. After putty dries do you use a whiting powder to clean the stained glass work?

I appreciate your recommendation and response.

Hi Dennis, my page of recommendations is here and the putty is under the ‘Assembling – Lead Came Technique’ section. I’m happy you’re finding my stained glass site useful, thanks 🙂

I clean with whiting straight after puttying – it’s particularly important to get the putty off the stained glass lead came – and then leave the panel for a couple of days before picking out the last bits of putty before the final polish.

Hi Milly,

Great description, very informative. I have one question:

I am making a stained glass panel to fit into my front door. There is a difference of 72mm between the tight and sight size, this is much thicker than the border lead so what do I do in the bit you don’t see?

The ‘Sight’ size is just for design purposes. So you would make your window to the ‘Fitting’ size but make sure that everything you want to actually see is within the ‘Sight’ size. For example, if you had a dog’s nose close to the edge you would want to make sure that the nose isn’t visually chopped off by being behind the fittings. The nose needs to be within the ‘Sight’ size.

The glass beyond the ‘Sight’ size makes the window fit. I hope that explains it.

Great question Joanna, thanks.

I found the examples of soldering lead joints ineresting and informative also I liked the was to measure, cut and fit a glass panel into an area.

Thanks

Gary Skipper

Glad the tutorials were of help Gary. Thanks for your comment and good luck with your future projects.