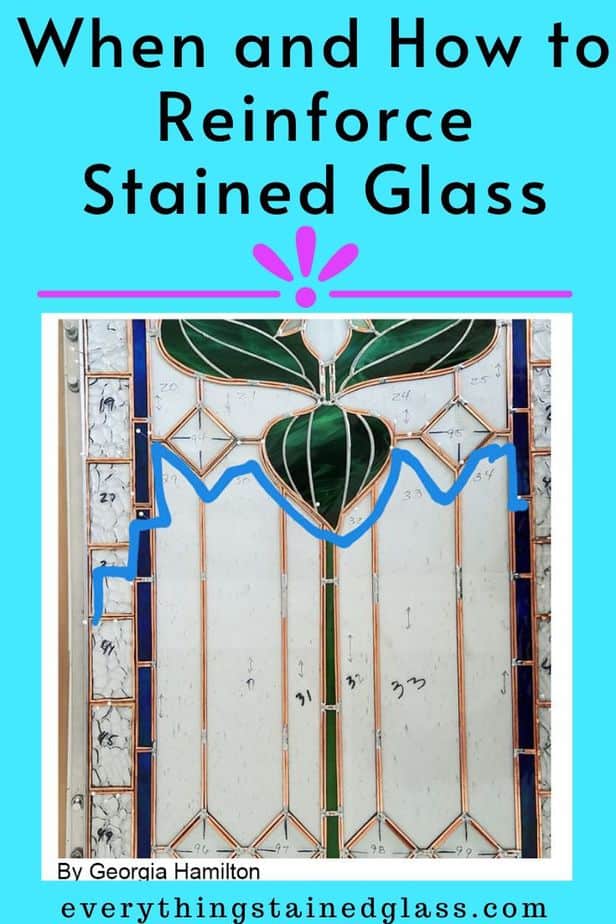

How to reinforce stained glass is a question I get asked over and over and OVER 🙂 Sadly, there isn’t a ‘catch all’ answer. There are many different factors to take into consideration when reinforcing stained glass windows and they’re different with each window.

When To Reinforce Stained Glass Windows

Here are a few of the factors you need to take into consideration:

The Design

This is the most important. If it’s balanced with a mixture of large and small pieces of glass, with lead lines both vertical and horizontal your window will be inherently stronger and need less reinforcing. This is the ideal situation!

The Frame

The best solution for stability is 1/2”/12mm puttied lead came around the edge and then fixed in a wooden frame. You can use zinc if you prefer but it’s more time consuming and a bit of overkill if you have a wooden frame too.

The Position

Is your panel internal or external? South or north-facing? These are all important things to take into account when reinforcing stained glass windows.

I use the following as a general guide:

- Panels that are static – and by that I mean an non-opening window or door = perimeter more than 10ft needs reinforcing (some say 12 ft but it’s always better to err on the side of caution)

- Panels that move – a window or a door = perimeter more than 8ft needs reinforcing.

- Add reinforcing right across your panel every 18″/450mm or so. It can’t stop halfway across, mind! It has to go from edge to edge for strength.

The bottom line is that reinforcing solutions vary greatly depending on your design and window location.

Main Methods of Reinforcing Stained Glass

There are many different ways of reinforcing stained glass windows. These are the main groupings:

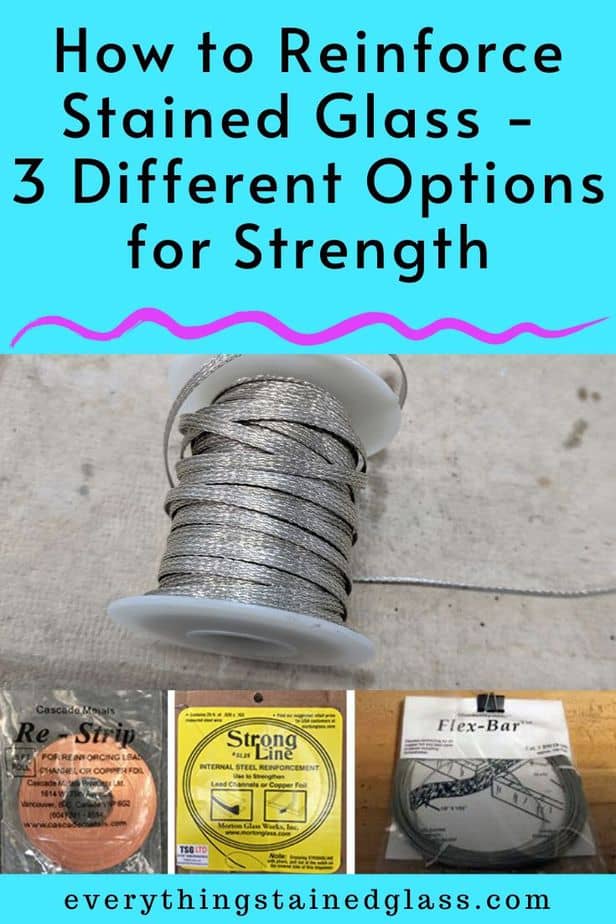

1. Metal Strips

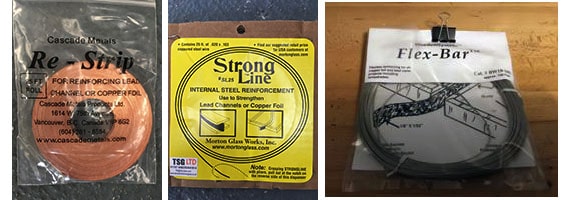

Copper Re-Strip, Morton Strongline or Flex-Bar, a braided copper strip. They are collectively referred to as ‘Fins’. They are inserted in between foiled shapes or next to the heart of lead came (not braided wire for lead) and are bent to shape. They can crisscross your panel.

You can get them on Amazon here:

(*Just so’s you know, if you click and buy through the * links within 24 hrs I get a small % from Amazon, (not you!). Thanks in advance but no worries if you have a local store – I’d always support them first 🙂 )

2. Lead Came

There is also reinforced lead came available that comes with a thin strip of brass or steel running through the heart of the came. This doesn’t bend easily and is good for straighter lines and larger panels.

3. Metal Rods

Saddle Bars are round metal rods added after the piece is assembled. They are drilled and fixed into the window frame and copper ties soldered on the stained glass are twisted around it. Alternatively Flat Rebar are flat metal rods which are soldered on to the face of the came in place on the inside of the panel to keep the entire work from flexing.

Methods #2 and #3 are generally used for reinforcing large external or moving stained glass windows. Techniques #1 – Metal Strips – are more usually used for copper foiled work so I’ll concentrate on how to reinforce stained glass with these.

How To Reinforce Stained Glass

Placement isn’t too difficult if you remember these rules:

- The strongest reinforcement runs the shortest distance from edge to edge

- Reinforce perpendicular to a lead line that might fold. Parallel lines and borders are good examples

Reinforcing Stained Glass Using Re-Strip & Strong Line

Copper Re-Strip

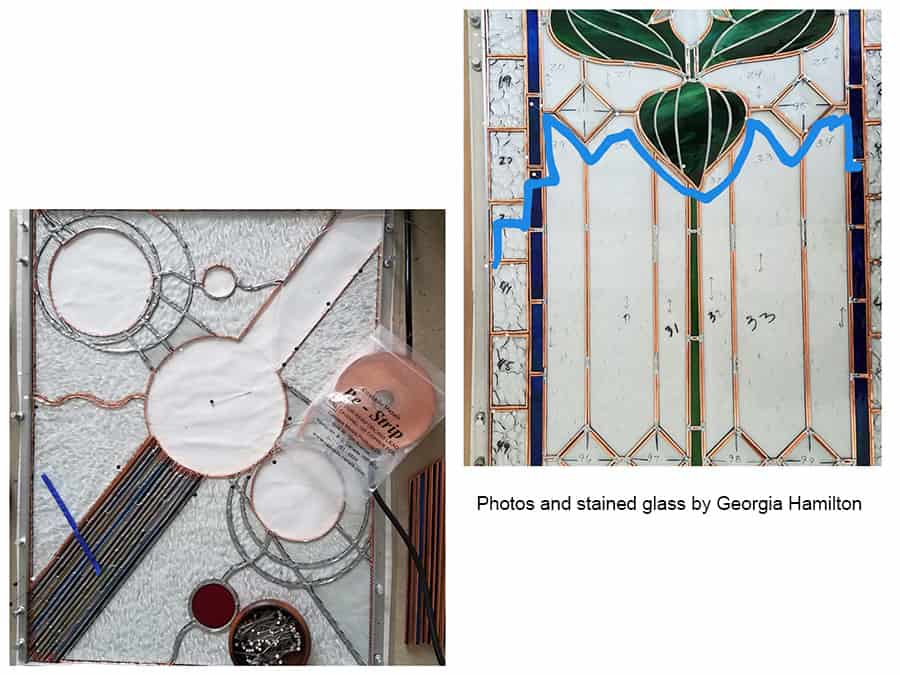

The Re-Strip* (paid link) is 10 mil thick and has a bit of a life of its own. You can see it being used in the left-hand panel, above.

- Re-Strip does sit higher above the glass a little but this is hidden once you solder the seams. Georgia used this to her advantage because the centre plate that it supports was heavy and stuck out quite a bit from the panel.

- She soldered the backside first so that the circle was proud at the back and not the front of the panel.

- Pins were used to hold the Re-Strip in place. You can use masking tape across the top of the glass instead of pins to stop it from popping up.

- Lightly tack solder it in as you work it around.

- Use bent nosed pliers to bend it around corners.

Pros and Cons: Re-Strip can be used with Lead Came. It’s effective and invisible. Some people find Re-Strip a bit difficult to bend as it’s very stiff.

Morton Strong Line for Reinforcement

Morton Strong Line*(paid link) is heavier than Re-Strip at 20 mil thickness. It jumps about a bit as you are assembling your stained glass panel. You can try using horseshoe nails to keep the end you are not working with in place so it doesn’t jump around.

As with the braided wire (below), you have to shave a mm off your glass piece to accommodate the width of the Strong Line. This is to stop your panel growing bigger than your pattern. Not desirable!

Strong Line is good for panels that have straight-ish lines and that don’t have many complex shapes to bend around.

Pros and Cons: It’s very strong and effective. It can be used with lead came. It’s a bit tricky to manipulate but makes up for it in strength!

Using Flex-Bar for Reinforcing Stained Glass

Flex-bar is a braided copper reinforcement originally used for reinforcing lamps. The solder drips into it and stiffens it during assembly.

Georgia used it for stiffening and reinforcing across the centre of the panel, right above. The blue line shows roughly where the braided reinforcement was placed.

- It is the same height as the glass so it didn’t matter which side of the panel I tack soldered it into first.

- It is wider than Strong Line or Re-Strip so you’ll have to work out where it’s going to go BEFORE you cut your glass. Cut the glass a bit smaller along this reinforcement line to leave more of a gap to accommodate it. Because of this, it makes your solder seams wider, which may bother you.

Pros and Cons: It’s easier to use than Strong Line or Re-Strip as it’s more flexible and good for complex lines. Good for arthritic hands! It uses far more solder and creates a wider solder seam.

Which Metal Strip Is Best?

I think all three have their uses, depending on your design.

Using Strong Line, ReStrip or Flex-Bar next to the heart of the came as reinforcement is great choice because it’s internal and therefore not visible from the outside like saddle bars or flat rebar.

You can get them on Amazon here (paid links):

(*Just so’s you know, if you click and buy through the links within 24 hrs I get a small % from Amazon, (not you!). Thanks in advance but no worries if you have a local store – I’d always support them first 🙂 )

Reinforce Larger Stained Glass Panels With Metal Strips

With these Strong Line or Re-Strip solutions I would:

- choose 1 or 2 straight-ish central line/s (depending on the height of the panel) and cut the metal strip a couple of inches longer at each end.

- bend the strip upwards at either end a couple of inches and solder these ‘tails’ into the lead or zinc frame.

- melt some solder in the inside of the frame to hold the metal strip in place. Do this by working it in at the solder joint along the area where the braided wire is sitting.

This effectively holds the weight of the top half/third of the panel above the reinforcement line.

Big thanks to Georgia Hamilton for sharing her helpful storyboards for this page 🙂 Georgia is a student of my online stained glass classes and a member of my private student FB Group the Stained Glass Hub.

Reinforcing Questions

Question: Should the reinforcing go horizontally or vertically?

- The basic principles are if it’s a tall narrow window, go across with the reinforcing.

- If wide and short, go vertical.

Question: When I solder the panels together do I need to reinforce the panels before soldering? If the answer is yes how should I do that?

I have designed and created 3 stained glass panels separately and now want to put them together to make a single rectangular panel for a transom window 66″ in length (actually I am doing 2 windows). Each single panel is 22″ using foiled technique. I plan to go around the perimeter with U came.

I have attached my design that measures 10 7/8 x 66. There are (3) panels. Starfish, Chairs, and Starfish again. This will be placed on the inside of the transom windows using silicone or small window molding.

Milly’s Reply:

I would add 2 vertical supports (as per the turquoise lines). Make them longer and solder them into the U came frame. See instructions above under Reinforcing Larger Panels With Metal Strips.

The moulding will give the edge some support too.

Question: Saddle Bar Attachments

I’m fitting some restored stained glass panels into new wood frames. The panels are roughly 1m 26cm (4ft 2″) high so I’m fitting saddle bars horizontally in either 2 maybe 3 placed to tie the panels too. How do I fit the saddle bars to the framework? Should I just make the saddle bars the width of the window and once the panel is tied would that be sufficient?

Milly’s Reply:

Work out where you’re going to place the saddle bars and drill 2 (or 3) holes on both sides of the wooden frame, one about 2.5cm deep, the other less, say 1.5cm. Their diameter must be big enough for the rebar to go in.

Then place the window in and insert one end of the rebar into the deeper hole and then centre it so that there is an equal amount of rebar in each hole.

You can wedge them in with small slithers of wood and/or putty around them and paint when dry.

No, you can’t have the rebars the exact same width as the window. They have to be cut longer and go into the frame to add strength.

PIN IT FOR LATER!

Other stained glass tutorial articles on the site that might interest you:

Thank you for this post (though your whole website has been very helpful)! I am going to make a bigger sized piece than I am used to, approx 17″x12″, and I’m wondering how much reinforcement it needs. From this post and the comments, I’m thinking a zinc came border may be enough, or would you recommend using re-strip as well?

It depends on the design Sofia, and where it’s going to be hung. Free hanging panels are more vulnerable (torsion) so I’d put some reinforcement in that. If you’re on the cusp with sizes, it’s always better to add reinforcement than not.

I hope that helps.

Hope you can assist with a project I’m working on. I am planning an 11” by 81” transom window and looking for structural support ideas. It is a western scene with flat topped mountains across the middle, some cactus and houses across the lower half. The sky has a 2 or three ground lightning strikes. My plan is to reinforce across the mountain tops and connect reinforcement from top to bottom using the lightning and cactus lines. Question is, can I connect vertical bracing to the horizontal bracing? Will this be enough reinforcement?

Assuming that it’s 81″ wide, your reinforcing priority should be top to bottom – it doesn’t need horizontal reinforcement at only 11″ high.

I’d aim to get one every 18″ or so. The beading around the perimeter also acts as reinforcement, so make sure you make that a nice width (without cutting off any design elements of course).

Without seeing the design it’s hard to be specific but I hope this helps.

This post was so timely. Your suggestion to work the back side first when using reinforcing copper was just what I needed. I’m doing some pieces for raffling for my granddaughter’s senior “blast” and this made them look so much better. Look forward to your letters.

That’s great to know Ellen, thanks for taking the time to comment.

Does a 24″ stained glass skylight which will be lying flat on wood trim need to be reinforced?

Yes. Anything above peoples’ heads needs reinforcement and 24″ is of a size that would require reinforcement even if it were installed vertically. Good luck 🙂

Hello Milly,

I’m creating a 18″ wide by 36″ tall panel that will be copper foil. It is very organic with a couple of longer horizontal pieces across the middle of the window that I think will provide a good link of support. No lines go from edge to edge, and I think the interwovenness of the design should allow for no extra support. There are a couple of starburst sections that will probably end up looking like blobs of solder, but they are near the top so will not be weighted heavily. It will be framed with zinc and then inset into a wooden frame. I do not expect that it will ever be exposed to the elements or mounted on a door or any moving object. Any advise on support from this description?

I would reinforce in a couple of places across the 18″ width of the window as minimum. Any additional weaving of ReStrip or similar from edge to edge will only strengthen it further.

Hope that helps.

i ALLWAY PUT THIS

https://www.amazon.com/dp/B09JG2HRBJ/ref=sspa_dk_detail_0?pf_rd_p=b9951ce4-3bd8-4b04-9123-0fda35d6155e&pd_rd_wg=vQ0Qi&pf_rd_r=N3PSJXW98WF0HQ59VSZP&pd_rd_w=es8wl&pd_rd_r=16c475a9-e86a-4210-81e0-85d8c2c7498a&s=home-garden&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUEyV1ZLTVJBNzM5VTRFJmVuY3J5cHRlZElkPUEwNDczOTQ1M0g3QTg2SFFHOEg5VyZlbmNyeXB0ZWRBZElkPUEwNTA5MzM5MjkyTkNHNk42OEE4RSZ3aWRnZXROYW1lPXNwX2RldGFpbCZhY3Rpb249Y2xpY2tSZWRpcmVjdCZkb05vdExvZ0NsaWNrPXRydWU&th=1

around my pendant or ‘mobile ‘ like this if I have a break somwhere they still all attach and do not fall on floor

That’s a really useful tip Jacques, thanks for sharing with everyone.

This kind of tape can also be used to reinforce panels, like ReStrip and Strongline.

I am trying to reproduce a piece exactly like one of the panels on the side of my door (110 year old house) to free hang (no wood framing) above a new opening between the kitchen and family room (original dining room). The piece ideally will be about 5′ wide by 10″ in height. Would puttied lead in some of the vertical bars as well as the outside frame be the best answer? Also… still new to this… is that how I make the loops to hang it? I assume I will want to support it at 1′ intervals to support the weight.

It’s very hard to make reinforcing decisions without seeing designs Rachel. I’m not fully understanding your comment ‘Would puttied lead in some of the vertical bars as well as the outside frame be the best answer?’

Puttied lead is standard construction and isn’t a reinforcing method although it does help with rigidity. I’m not understanding what bars, sorry.

You’d need to add some internal support to the verticals as stated above – Strongline or ReStrip, or reinforced lead came (it comes with a steel core).

Sorry I can’t give specific help.

Hi Milly, thanks for all these thoughts on reinforcing stained glass. i’ve been asked to make a stained glass tattoo machine. The client does not want this made with clear glass surrounding it and framed, as she wants to hang it in her store window as just the gun. The machine is 3′ long and average piece size is about 4″ wide. If I use the reinforcing tape you suggest, will this support the weight of this piece as it hangs in her window? Many thanks for any thoughts.

With a piece that long that’s free-hanging, you’re going to need something around the edge to hold it steady so that it doesn’t bend – internal reinforcement or not. You could either use zinc or lead, making sure it’s puttied and that the ReStrip attaches to each side.

I hope that helps.

she can also use a zink add of a iron bar inside

I make that and sometime add wellding the iron bar whit lead and welding it whit a propane torch

also amybe add a wir at botton in a kind of triangular about 2 inch at center to the end like we see on bridge

Hi, Milly!

I am making some pride flags suncatchers (6 inches by 4 inches overall), so the whole thing is hinge-points — 6″ strips that are as narrow as 16mm on a 6-stripe rainbow. I have the strips foiled and ready to assemble, but I wondered what I can do to add a little more structural integrity to these. Would a frame of brass wire around the entire suncatcher help hold everything together? Thank you!

Your best bet would be to add a thin frame around the edge – in glass. More work I know but with stripes going right across the whole design is weak in terms of stained glass.

If you decide to go with the wire perimeter, it’d be better using ReStrip or Strongline but that’s tricky on 90 degree corners.

Good luck!

April, why not make the flags as blowing in the wind, i.e. wavy lines , for strength?

Mike.

Hi Milly,

I hate to say this, but I am working on a 22 foot by 2 foot high sign in copper foil. Argh! There are many thoughts of how to put it in a steel frame of angle iron and I was planning on using restrip every 12-18″ vertically. I have made a big window before, 82″x42 high. It actually held up well under some unusual abuse until it fell out of a rotted frame on a windy day and was all but destroyed.

So I am wondering if you have any suggestions. There are also many wide gaps that need to be filled. I wondered, reading this page, if I should use the strong-line to help fill those gaps. At the bottom edge there is a stretch that is 7’5″ that is 1/4″ from the edge. I wondered about putting 1/4″ U channel came in there. Also, on either side of that stretch there is about 4′ total of where it is 1/8″ from the bottom. It is all curves, large and small pieces. Do you think that using the super-line will

help fill those gaps? Should I use it along the bottom too? Wish I had someone to talk to whose brains I could pick. thank you kindly.

That’s a very wide sign Rose. I would make and install it in sections, edged with H profile lead to straighten the edge and ‘disappear’ those gaps along the edge. Good luck with it.

Hi Milly,

I have designed 6 panels 31″w x 25″ high. They will be installed permanently in the local library window with just a 1/4 inch on each side. (Measured each window 10 times to be sure of the fit.) There is a small concern about a fold potential. There will be 6 – 5.125″ square clear dew drop pieces going across the top to let in light but hide the ugly pinkish stucco. The panels were designed include a zinc H came to connect them to the lower section. Will I need more reinforcement that that?

It’s hard to visualise your window Kim. If you have a straight line going across it’s good practice to reinforce it with StrongLine, ReStrip etc – from side to side to reduce bowing potential.

Good luck, sounds like a great commission.

Hi, I’m making a piece that is comprised of 25 – 8 inch squares. The finished panel will be just over 40 inches square. Each individual square will be a single layer of fusible glass with elements tack fused to each one, making the glass just a little heavier than if it was single layer. I’m planning my heaviest pieces for the bottom of the window and going lighter as I get to the top. I plan on using zinc came for my piece, U came for the outside edge and H came for the inside pieces. This will be mounted on an interior south facing window that doesn’t open. Will I need to reinforce this piece? I was thinking of cutting the vertical H came into 4 foot lengths and the horizontal into 8 inch pieces. Thank you in advance for any advice you can give me. I’m not sure if this is the correct place to leave a question or not.

Yes, you’ll definitely need to reinforce this at 40″square Lynne. If I’m understanding correctly, the lines will be straight and therefore vulnerable hinge points.

The good news is that precisely because they’re straight, slipping ReStrip or Strongline into them is easy 🙂

Hi, I am working on a 30×40” panel that has alternate sized pieces in rectangular and square design, about 40 pieces in all. It will hang from the ceiling, near the front door. I was planning on framing with zinc (but could also put a wooden frame over that if necessary. I have already tinned the whole project, is it too late to use copper restrip on it?

You should design the panel with the reinforcing in mind at the beginning MJ. This is because you cut the glass a tiny bit smaller on the line of the ReStrip to accommodate it. You could try and put it in now and see if it has an adverse effect on the total size of your panel.

I would definitely put a wooden frame around something that’s hanging over where people walk.

Hope that helps.

Hi Milly

I’m making three transom windows that are separated but over glass sliders.

Two are 15″tall by 69″ long, the third is 15″tall by 72″ long.

Design is frank Lloyd Wright similar, created in lead.

Windows, will be placed inside against the current clear window, hel in place with quarter round.

Do these need vertical rebar strips?

Thank you.

Yes, I’d go for a vertical reinforcements roughly 18″ apart. If it’s not moving parts you could use ReStrip or Strongline.

I hope that helps.

I am constructing a 24×26 inch panel (using lead came) that will be sandwiched in between two ordinary pieces of window glass into the door’s window. Except for the outside edges, there are no lines that go straight across the entire window. There is a narrower border that is about 3 inches inside the outside perimeter of the window that goes all the way around but does not extend right to the outside edges. If I used copper restrip to strengthen the panel, would I put it on both sides of the lead that follows that narrow border? Or just on one side? And will it do any good since it doesn’t go all the way to the outside edges of the panel? I would have liked to send you a picture to help you visualize what I’m talking about but can’t seem to make that happen.

It’s not so important to reinforce if you’re sandwiching glass between two pieces of window glass Arlene. I would use tempered clear glass in this instance, as it’s for a door.

You’re correct that the ReStrip needs to go from edge to edge – something that needs to be factored in at the design stage. It goes in one side of the lead only.

I hope that helps and good luck.

Hi, I’m trying to make two insets for interior French doors. The panels will be 14×65-ish. Design separates the inserts into thirds, and I was going to reinforce each 1/3 dissection with the hard copper strip. The panels will be framed in zinc before being put into the doors (and held in woth trim strips). Copper foil method and I *think* a decent mix of larger small and medium sized pieces of glass. Should I also add rebar across the 1/3 dissection line and reinforce elsewhere or would the hard copper strips throughout be enough support? I really don’t like the looks of rebar for a narrow panel on a door seen from both sides… And I’ve never done one before so its bound to look sloppy, or so I worry…

If this was for a static door I would say that, with appropriate width quarter rounds/beading/trim strips around the edges, this would be sufficient.

Things that open – doors and windows – normally need more reinforcing. If it’s for yourself and you’re confident that you won’t be slamming or treating the doors roughly you could choose not to add the rebars.

Good luck.

I have designed 6 panels 18×30 that will be installed in our village library of my retirement village. There will be 6 – 5″x5″ clear dew drop squares that will be going across the top to keep thing light. 3 of the panels have additional designs in the top, like cats to look like it is sitting on a shelf or the steam from a coffee cup. 4 of the lower portions will be books with additional characters sitting on the books, A mouse, Russel terrier with a ball, a calic0 cat and a coffee mug. the middle two will have an underwater fish & kelp (everything represents something in our village)

When completed they will have a zinc came as a frame for support. They will be installed to a fix non opening window with multiple “pegs” on each side going into all 4 walls to hold them in place. Each panel has it’s own window.

We live in Florida & Heaven forbid a severe hurricane should arrive, we wanted to be able to remove them for safety or if damage is done to the library, remove them as repairs are done Should I still consider reinforcing them?

You’re a great inspiration by the way

I can’t quite visualise the layout of the design to ascertain whether there are any weak spots Kim… are there any straight lines that go from edge to edge? These are vulnerable if not reinforced or held in sufficiently robustly from the frame.

The perimeter is under the 10ft I recommend as a minimum but this is not fixed in stone; if the design is vulnerable the perimeter measurement isn’t that helpful.

If you could secure them all round with quarter rounds or similar rather than pegs that would help.

I hope that helps.

Hey there, I am working on a pair of 2′ x 3′ panels that are going to be installed into steel frames above a doorway. The design is well balanced and I’m using lead came, would you still reinforce?

The rebate in the steel frames will help with stability, especially if they’re deep – say 15mm. You’re right on the cusp with reinforcement at 10ft perimeter. You should be okay if the design is well thought out 🙂

Hi I am making a leaded panel that measures 13 inches tall by 46 inches wide. It is framed by 1/2 inch zinc. It has many vertical and horizontal pieces. It will also be framed with oak to be a wall hanging. Do I need to reinforce it?

I would just choose a couple of evenly spaced verticals and reinforce them with ReStrip or similar Carolyn. Sounds like a pretty robust design and it’s inside too but best to be safe and it’s not much hassle to do this.

Hi Milly,

I have a vertical door panel with perimeter just over 11 ft; the door is internal (inside the porch) and will be fitted with grilles over the panel. I am wondering if the grilles will take on the function of the reinforcement or not, would you say it’s necessary to reinforce the panel itself?

Many thanks 🙂

If the grilles are robust and you can find a way to attach the stained glass to them this would work Diana. You could solder tinned copper wire (you can patina to match solder colour) to strategic parts of your window and twist said wire around the grille. Good luck!

Hi, I am making 2 small copper foil panels for an internal door. They measure 330mm by 150mm and the pattern is oblong strips placed in a brickwork pattern that runs vertically. Although they are only small, do you think these should be reinforced due to the hinge joints. Many thanks.

Yes, from what you’re describing. Doors and windows always need more reinforcement and if you have hinge joints even more so. Hinge joints are easy to reinforce though, which is a good thing! 🙂

i have a panel that will be 10.175” x 28.250” (lead came frame and foil construction it will be framed in over a doorway like a transom ( no door and it will not move unless we have an earnthquake) the perimeter is a little over 6 ft i don’t think i need to reinforce but just want to double check

Ha, let’s hope for no earthquake Paula 😉 You’re right, you’ll be fine with this if the design is nice and balanced.

I like to make small, 3-dimensional stained glass pieces using foil. (flying dragon, bee mascot, leaves and flowers on a copper wire wreath) I have trouble with the joints bending and coming apart, even with heavy solder. I live in Florida so it is humid here. That also contributes to the glue easing lose. I never try to mail these items as they are so fragile. Lately I have been thinking that I need to move to lead and hobby came for these projects but I’m still not sure how to make the 3-D joints strong. I have never used lead came before but I have used zinc came. The zinc is strong but not flexible enough for the projects I would like to make.

You can stick hobby came (very narrow lead came made for sun catchers) around the edge with E6000 glue Jo Marie. It finishes them off nicely but it won’t give them any more strength. The only way to truly get around this is to design them so there isn’t any ‘hinge’ points – straight lines that go from edge to edge. You could try adding small shapes in to break the line up and add strength.

I hope that helps.

Hi Milly, I’ve a large panel to make 77″ high 30″ wide…the pattern does not have a strait line anywhere lol…how would you reinforce this to keep it in one panel, or am I crazy to even try one panel..any suggestions would help

Something this big needs some serious reinforcement. Ideally metal fins or bars drilled into the wooden frame with ties soldered to it. I wouldn’t do a window this big unless I had thought of how to reinforce beforehand.

Can you divide it to make it easier for yourself? That’s what I’d recommend in this situation.

Sorry to be a doom-bringer!

I don’t understand how you are saying to make the Reinforce Larger Stained Glass Panels With Metal Strips section work… Is this for a leaded window? how do you solder the metal strips inside the zinc and then insert the glass?

Copper foil and lead. Solder the upturned edges last, after you’ve inserted the ReStrip/Strong Line in between the foiled glass/lead heart and glass. With foil, hold the ReStrip down with masking tape or similar until soldered.

I hope I’ve explained it more clearly now Bridget.

Hello! I have an old 27” round window that is going to hang free from chains in an arch way. It is in good shape but a little bendy when being lifted.I have a carpenter building a round frame for me. I was planning to reinforce it so it is easier for the carpenter to handle while installing the frame. It also has a piece of rebar attached that runs through the center. Is soldering copper a good was to enforce it? Also, there are literally no straight lines at all.

Thank you for any information.

Copper wire won’t add any appreciable strength to a window this size Jennifer. Adding any of the metal strips would mean dismantling it so that’s definitely not going to happen! The best thing you can do is make sure that the edging zinc or lead came is in the best shape it can be for the carpenter to move it into the frame. Once installed in the frame the frame itself will provide the extra strengthening you need.

I hope that helps. It sounds lovely!

Hi, FYI, the links to Morton Strongline point to Restrip.

Is it available in the UK?

Love the e-book.

Mike, Scotland.

Ah, that’ll be because Amazon is trying to find a similar product (but can’t) in the UK Mike. Thanks for the heads up. You can get it here at Tempsford Glass.

Thought I’d share my observation with Strong-Line. I have used this when I needed a nice stiff piece of metal as support on the outside of glass items, but not in between seams as it’s normally used.

Unlike Re-strip, Strong-Line is not a solid piece of copper, it is steel that has been copper plated.

In every situation that I’ve used Strong-Line I’ve noticed that the copper plating on the Strong-Line gets sucked up into the solder, leaving the steel metal exposed. This has caused difficulty (for me) to make a good, reliable solder joint; the solder doesn’t want to stick very well to the steel.

In a situation where Strong-Line is used in between pieces of glass, and the seam is filled with solder, that might not be an issue at all. Since the metal strip is there to prohibit the glass from flexing, and the solder should fill the cap between the glass, the solder should also encapsulate the Strong-Line.

It might not be so critical that the solder is attached (wetted) well to the Strong-Line as long as the solder is covering it all the way around.

This has happened when I used either Nokorode paste flux, or Glastar Gel flux. I use a Hakko 601 iron.

For anyone who has not seen or used Strong-Line, it is thicker than Re-Strip so it would fill a wider gap. It is also much stiffer than Re-Strip so it is more difficult to make it bend to go around sharp angles.

Thanks for your comments about StrongLine Gail, very helpful for others to read about others’ experiences too 🙂

Thanks for the page as this is a little discussed topic. While they are technically windows, I make a lot of glass tables. I learned about strong line when I was making a particularly large project. I went to my local store and asked for re-rod, as a tabletop will sag without reinforcement. They don’t sell re-red but they sell strong line. It worked great for the table — it adds a nice amount of rigidity. For a large table, which is normally rectangular, run the strong line up both sides of the lead on the shorter width of the table, in as many places as you can. I tried strong line once with a copper foil project — it’s too unyielding, so the re-strip is definitely the better choice for those projects.

Great and helpful comments Carmen, thanks so much for adding them for others to see.