Question about Glass size on a slumping Mold

I am trying to slump glass, and wanted to ask about the glass size on a mold. Should it be smaller than the mold when you cut it?

I have just only really started working with glass recently. Your work is really inspiring, and your techniques and tips really helpful, but also makes me see how little I can do at the moment.

thank you, Joanne

Milly’s answer:

Yes, good question. Cut the glass just a little bit – 2-3mm – smaller than the mould. If you were to cut it bigger than the mould, it would fold over the mould in the slumping process, giving your bowl (or whatever) a lip. This could be OK, but not if you can’t separate the glass from the mold.

Let me know if I haven’t made it clear – words are quite difficult for explaining sometimes.

Thanks for your enthusiasm about my work, it’s always really nice to hear. Great to know that someone’s finding my website helpful, too!

Good luck with your projects.

Slumping Mold Mix

I want to make a glass slumping mold. Could you please recommend a mold mix for me to purchase. Or if I should mix my own what materials do I use and of what proportion. Should I drill small holes in the cavity to let the air escape as the glass slumps? If I let it dry for a couple weeks would the mold be ok to use without a firing to dry? I ask this because I dont have my own kiln yet and will be charged per firing.Thank you so much for your help. Keith

Milly’s reply:

Hi Keith, thanks for your interesting question. I always mix my own – that way I can make it a bit runnier if I have some very delicate marks to pick up. You can find the recipe – and other tips – here on my Glass Mold Making Instructions page.

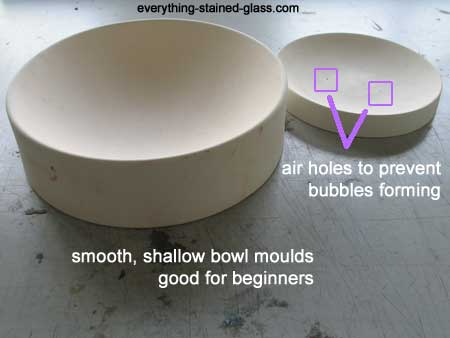

Small drilled holes are a good idea to prevent the glass misshaping or bubbling up in the firing. Drill them at the lowest point of any ‘dips’ in your mould. I use an old-fashioned hand drill, as molds can be a bit delicate – but you might be handier with an electric drill than me!

Yes, twChriso weeks should be fine for letting the slumping mold dry out and preventing an additional firing.

Hope your glass slumps to perfection!

Materials for Mould Making

Where would I find the type of flint needed to make slumping moulds? I am new at this and would like to learn the technique so my students can attempt the process in my sculpture class. I am right in understanding that using plain plaster would not work? I believe that I can use regular clay – what cone is best?

Thanks for your help.Chris

Milly’s reply: Your students are going to have fun! I buy all my materials for glass mould making from a pottery supplier – flint, grog and plaster.

You could just use plaster on its own, but the mold won’t be very strong and is likely to crack at the temperatures needed for slumping. The flint and grog strengthen the molds. You could risk it though, if it’s more about process than finished result; they should last for one firing.

You’re right about using regular clay – I use the cheapest available. If you’re biscuit firing it, don’t forget to brush batt wash on it after the clay is fired and before firing the glass. It works as a separator, otherwise the glass will stick to the mould.

Cones – you need numbers 14,15 or 16, depending on what your top temperature is (14=1540F/138C, 15=1479F/805C, 16=1458F/792C). Have a look at this Cone Firing answer for information on how to use them.

Good luck Chris, hope that helps. Let me know how your students get on?

In addition to cutting 2-3mm from mold edge, how would you handle the width on an s-curve shaped mold?

In the same way Kasha, leaving a little room around the edge.

If the glass is not cut to accommodate the extra area because of the curves, will the design stretch when the piece is slumped?

Thanks so very much!

The curves in moulds are usually subtle so you won’t see the ‘stretch’. If you took a piece with a steep up and down curve it would stretch over, yes. And be weak!