Increase Your Cutting Options

You’ve got your stained glass pattern and you’re wondering how to approach cutting glass shapes. Is it best to use a template? And if so, do you stick the template on or do you trace around it? What about the “English method” that you’ve heard of but don’t quite understand?

There’s always more than one way to do the same thing in stained glass, and cutting glass shapes is no exception. The good news is that you can start with the one that suits you best and as you build up your skills and confidence you can add the others.

Before you know it you’ll be ready to cut any shape in any glass.

If you’re struggling with accurate cutting there are many easy-to-learn techniques that will help you get better.

If you don’t have a local class my short Conquering Curves course has taught lots of people the skills to cut shapes accurately. And we all know how important neatly fitting shapes are!

The course is self-paced and online so you can learn these cutting techniques even if you are unable to get to a class. You can find out more about it here Conquering Curves.

1. Cutting Stained Glass Shapes – Tracing Method

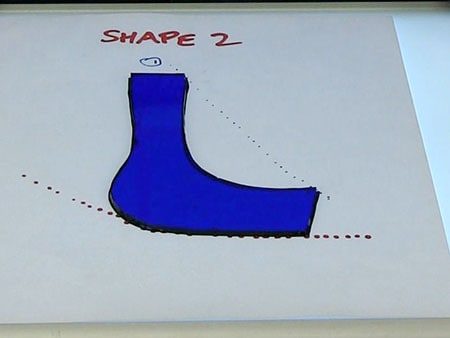

Carefully drawing around each template shape on to the stained glass before cutting just inside the traced line.

When best to use the Tracing Method?

- Works with either light cathedral (transparent) or opaque stained glass that you can’t see through.

- If you’re using it with dark cathedral glass you’ll have to use a pen that will show up on the dark colour. Those gold Sharpie permanent pens are good for this (affiliate). The marks are waterproof and you can remove them with paint thinner – odourless!

- If you’re using glass that’s very irregular it’s sometimes hard to trace as accurately as you need to cut stained glass shapes for a perfect fit.

The technique is very simple:

I’m assuming that you can already cut glass. If you can’t here’s my glass cutting tutorial for you.

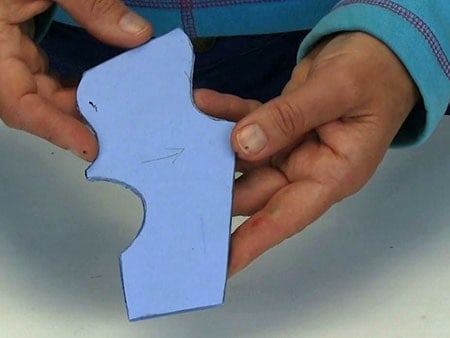

- Cut out all the individual shapes in your pattern from stock paper (thin card). You can do this either with regular scissors or with foil pattern cutting shears.

- Make sure that these template shapes are 1/32″ (1mm) smaller all the way around than the shapes on your pattern. This is to allow for the thickness of the foil when you wrap it around the glass.

You can see more detailed instructions for cutting your pattern here. - Put the templates on the pattern all at the same time to check their accuracy.

- Hold your template shapes absolutely still on the glass – taking care to get the grain direction going the correct way – and draw around it with a fine permanent pen (Sharpie)

- Then cut – and this is very important – on the inside of the black line.

If you don’t do this, your glass shapes won’t have that 1/32″ (1mm) gap in between them that you need to get your stained glass project to fit together. It will all get bigger and bigger and bigger! - Repeat for each of the stained glass shapes.

Summing Up

Lots of people find this method the easiest and most versatile but it can add time because you have to cut all the template shapes out first.

It can also lead to some accuracy problems as the templates can move when being traced or the pen is too thick.

2. Cutting Stained Glass Shapes – Templates Method

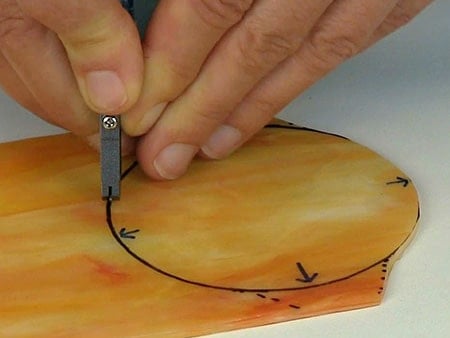

Sticking the templates on with glue before using their edge as a guide for cutting glass shapes.

When best to use this cutting glass shapes method?

- Works for any type or darkness of glass

- Not good if you’re wanting to be quick as this is the slowest method of cutting glass shapes

This is what you do:

- Cut out your templates from stock paper or thin card exactly the same as numbers 1-3 above.

- Using rubber cement (Copydex in the UK) or a glue stick, stick a template on your chosen piece of glass.

- Wait for the glue to adhere if necessary.

- Now make the score with the cutter wheel snug up against the template. If the wheel slips onto the template simply stop and replace it back to where it slipped off.

- Continue around the whole shape in this manner.

- If necessary, you can grind the edges a couple of times before the template gets wet and soggy.

- Repeat for every shape.

- Remove template only when you’re happy that the shapes all fit together.

Summing Up

This method of cutting glass shapes is reliable and consistently produces very accurate results. It can also be used on all types of glass which is a big plus.

The downside is that it is very time-consuming. But then having ill-fitting shapes wastes both time AND glass!

3. Cutting Glass Shapes – The English Method

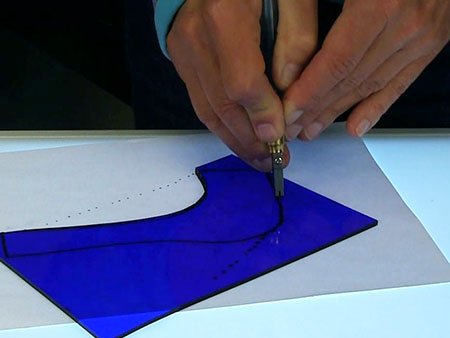

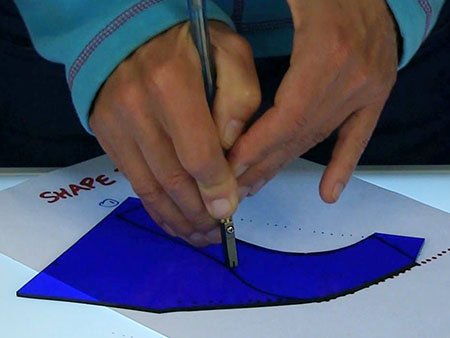

Placing the glass directly on top of the pattern and looking down through the glass to cut the shapes freehand.

When best to use this?

- Works well for light transparent (cathedral) glass that isn’t too textured

- If you have a light box it works well with dark cathedral glass too

- You can’t use this technique for opaque glass that you can’t see through

How to do it:

- If you are using dark transparent glass place your pattern on the light box. If you can see through the glass you can do this on your work bench instead of a light box

- Put the glass on top of the pattern

- Making sure that you are directly above the pattern and can easily see where you’re going, make the scoreline

- Don’t rush, go slow and steady. It’s not a race!

- Be careful to cut on the inside of the black pattern line to ensure that your shapes are the correct size

- Repeat for each cut

- Groze or grind the edges as necessary to tidy up

Lightboxes for Stained Glass

Vaughan Dibble, one of my online students, kindly sent this idea for a home made light box.

Summing Up

It’s a great way of cutting transparent glass quickly as there’s no extra steps – no cutting templates, no tracing around them and no sticking them on.

But there are some drawbacks.

It takes a lot of practice to become accurate at this method so results can be a little disappointing when you first give it a go.

It is only good for transparent glass which rules out all the opaques – a lot of glass!

Conclusion

If you do persevere and learn all 3 techniques you will have the best thing for a stained glass artist – options.

Your question won’t be ‘can I cut that shape‘ anymore, it will be ‘which is the best method to use to cut that shape?’. And you’ll have the confidence to cut them all.

There are lots more tutorials showing you How To Cut Stained Glass here.

Return to Everything Stained Glass Home Page.

I’ve been using Mylar, used by architects, for many years.

I copy my pattern on the non glossy side and write the pieces # and color on it.

You can use a spray adhesive if you choose to make it stick on your glass.

A great benefit to using Mylar is keeping the pieces with the original pattern in a pouch/plastic bag to reuse or to access for repairs .

I’ve done copper foiled glasswork for the past 45 years and have found this to be the best method for success.

A fantastic tip, thanks Peaceful Waters. Love your signature name too – very calming.

wheb I have multiple replica of one picture to do

like the byke break whell the picture around are all exactly the same

I use pencil dremmel ( the size of a finger ) and put a diamond file like a needle about 1 /8 diameter very fine

I first pass one turn around the picture after if I use a normal diamond cutter the cutter follow the round make by the veedle very easy to do complex by x6

also for my byke gear or braek wheel the center have lot of round curve

by passing the needle before the cutter all is very easy now

can do x4 easely

sorry a picture can be better

I know what you mean about photos Jacques – sadly there is no upload facility on this platform. Thanks for your explanation, very interesting.

if you built a light box

a good way to deam the light is to use a sheat of plastic that you c an find in front of a scrapt lead tv

go to junk make apart a led tv in f ront you can find a very good sheat of tansparent plastic about the size of 36′ per 48′

that is better then direct fluorescent

jack 47 71

Good recycling idea, thanks Jacques. You can also stick thick tracing paper on the underside of the glass to soften the fluorescent glare.

I found thick sticky paper on 1 side and just use my copier to transfer the pattern to the white paper. Cut it out and stick it on the glass to cut. Turns the pattern around in some cases, but most times doesn’t matter. The paper comes off easily while fringing, but you can always mark you pieces after grinding if you have a lot of pieces

Thanks for this Marcia, much appreciated.

Hi Millie

We tutor at a U3A class in Qld Aust. We use laminate sheets that have been run through the laminator without anything in them which makes them sturdy and strong. Then you can draw your pattern on the laminate and cut it out and draw around the pattern piece with your permanent pen onto the glass. We find that these laminating sheets are fantastic pattern makers instead of paper because they are waterproof and see-through.

If you wish you can keep the pieces to use again and again for your favourite pattern. As stated before, the laminate sheets do not get wet and you can use your isopropyl alcohol rub to get any marks off and use it for something else.

Cheryl and Trevor Fielding

Toowoomba Queensland Australia

Thank you for this Cheryl, that’s a really great idea and helpful for everyone. It’s a much more robust method and great for teaching people as they have a very definite shape to grind to.

Hi!

An easy way to remove permanent marker instead of rubbing alcohol is a dry erase marker. Just trace over the permanent marks and wipe it off..

Thanks for all your terrific information.

Sal

Thanks for adding this Sal, it’s very helpful 🙂

thank you milly as always great information

You’re welcome Ron 🙂

I took stained glass classes 20 years ago and it had me addicted. I collected all tools, supplies, equipment and lots and lots of glass pieces as everyone knows. I have been an artist and crafter all my 64 years. I recently (a week ago) picked up the stained glass bug again. I have watched many excellent videos on YouTube but I couldn’t find anyone to teach how to cut the patterns or the true techniques in cutting glass until I searched and found your very thorough blog. You taught me that one step I looked for to get refreshed. Thank you for your professionalism in explaining. Thank you sincerely, Joey – Brandon Florida

Oh Joey, that’s such a lovely comment to read, thanks so much. I’m delighted you’re coming back to stained glass and hope your journey is a creative one 🙂

I am thinking of using Printable Vinyl Sticker paper (for laser printers, since that’s what we have) (lots of options on amazon), since when I’ve tried paper templates, they dissolve quickly. Do any of you have experience with these?

Also, I’m moving from project-based classes to independent workshop time, and when I start a project from a book, I want to make sure I’m making enough copies. (I’m using _Modern Designs Stained Glass Pattern Book_ by Anna Croyle).

1 – one (or more) for coloring and deciding what it will look like — there are a lot of geometric elements in designs I like, so while the leaves will be green and the tulip pink, all the background rectangles — what am I doing with them? Which ones am I connecting as the same color or texture?

2 – one as a “cartoon” (even though I’m doing copper foil) to assemble it on. (When we had that for a suncatcher class, I found it helpful.)

3 – One as the cutting templates, which as I said, I hope I can do on printable vinyl decal paper

4 – one for my Project Notebook so if I want to go back later, I can see what I made, when I did it, list my glass choices and all that. That way _if_ I end up making things to sell in the future, I can use that to replicate items, estimate costs & time, or at least look back and see if I’m getting faster / better with similar projects.

Am I missing anything with my planning? Thanks!

It sounds as if you have everything in hand April. Brilliant. I could do with you next to me at the start of each project LOL!

Thanks for all your great advice and tips. They have saved me from and got me out of a few blunders.

In answer to the question about printable vinyl for patterns, that’s the method that seems to work best for me. The vinyl sticks to the glass well and doesn’t degrade as fast as paper during the grinding process.

I hope this helps someone.

Thanks Andy, I’m sure your comment will help others. The vinyl works well.

I have been doing stained glass for about four-five years now. Learning to mark the glass was my hardest lesson. After using several suggested methods I began my own system. I print the pattern elements onto card stock, cut out the pattern parts, then glue the parts using Elmer’s Glue Sticks. I use my brazing roller and also let the parts sit sometimes for the glue to dry more. Once the part is ground and ready to be foiled or camed, I place the part in shallow water bath and soak, the pattern will slide right off and easy to clean.

The negative side is that the sponge water will loosen the glue, especially on small parts.

Thank you John, that’s a very useful addition to the page. I love it when people experiment and find solutions that work for them… and then share them with us 🙂

Hi, I’m having problems finding the Cookie cutter for stained glass and wondering if you can help me, I have difficulty holding small and sometimes larger pieces to grind. Can you tell me where I can purchase one or perhaps even two of them to help me hold the glass in place

If you’re in the US you should be able to get the Grinder Cookie in Franklin Art Glass or similar Hazel. Creative Glass Guild stocks them in the UK.

Alternatively there are some homemade solutions here:

https://everythingstainedglass.com/grinding-stained-glass

I hope that helps.

I’m going to make a couple of wood cookies with irregular shapes. I always have a bicycle inner tube around to cut up and line the wood.

I was taught to cut one pattern piece at a time from freezer paper (waxy on one side) with waxy side up (lasts longer with the water) and glued down with a glue stick. If the glass is textured you trace on the paper side and then glue on the back of the glass with waxy side out so it is reverse. It’s probably a little slower but I start in the middle and work my way out so the pieces fit exactly together. You are tracing against the other pieces already cut and foiled. I suppose it takes longer. I would like to try something faster. Do you recommend the foil scissors that cut the 1/16″ when you cut on the drawn line?

Thanks for your useful recommendations for waxy paper Michelle. Very interesting and I can see how that would work well.

The foil shears are okay if you go slowly, bit by bit, rather than taking up a lot of paper at once. I’m not sure how they’d work with your waxy paper.

You could try adapting a box cutter to the correct width, as per this page: https://everythingstainedglass.com/stained-glass-how-to

Scroll down to Make a Double-Bladed Knife for Cutting Templates to find the instructions.

Thanks again 🙂

I love reading people’s responses! Admitting mistakes helps others and really is a blessing for those of us in the same boat!

I totally agree Billye. Everyone’s comments are so helpful and are adding up to such a useful and encouraging resource 🙂

I make my pattern and color it, then have b/w copies made at the stationers. ONE of these is then laminated and I cut my pieces out with the proper shears, then glue the pictures on to my glass with glue stick. (the other copy becomes my “cartoon” under the edge frame; the colored “master” is left on the wall to be sure I am cutting the right colors.) I can position many pieces on a single section of glass and cut away the excess in an order that minimizes the loss of glass. Grinding does not ruin the plasticized pattern pieces as fast. I leave these pattern pieces on until I clean them off, scrub the glue off, and renumber my pieces, saving the pieces of the pattern in case of a necessary recut. Foiling then happens on clean accurate pieces. MY biggest problem in a complex piece is the necessary gaps to allow for foil, once foiled, still compound the size of the whole panel and I must sometimes recut/grind to allow room. Still unsure why that would be when I use the gap shears throughout. nothing is ever easy!

Thank you so much for your detailed explanation Margo. I have a really nice image of you in your workshop with your lovely workflow, all organised and relaxing!

I laughed when I got to the end; the making process always throws up challenges, sometimes unexplained, that keep us on our toes 🙂 The fitting of the pieces together – why do they always shift and need a little grind?? One of life’s mysteries…

To keep sharpie lines on your glass while grinding, you can put a small amount of chap stick on the lines, and they won’t wash off! Very small amount… very thin application… you don’t want to gum up your grinding head.

Thank you Pat! Very helpful for everyone 🙂

I have also found that silver permanent markers last longer on the grinder.

While out and about I happened to find some artboard-mounted posters that a shop had thrown out and I took them home. (I’ve since found that I can buy this artboard at my local digital printers or get free offcuts from them.) They’re about 3mm thick and easy to cut with an art knife/scalpel. I find them excellent for templates to trace around with a marker pen and far easier to hold in place than thin card. More importantly, because they are rigid, I can also insert them into my lead cames as I go, to check that each piece is going to fit – or make any final adjustments – before I cut it in glass.

Oh what an ingenious tip Leila. I know exactly the type of board you’re talking about… I’ve never thought of that application for it though, thanks!

I have been struggling for years with arthritis in my hands and need to use the saw for most cuts. Have had the same problem as others trying to keep the line from washing off. I have stumbled on a method that works great. My wife is an avid quilter and uses a Brother Scan and Cut for cutting some of her quilt squares. I ordered some 12 inch vinyl squares and now make my glass patterns on her Scan and cut directly to the vinyl sheets. These vinyl pieces stick to the glass while cutting and I have never had one wash off. They are perfect for cutting right up to the line. This has made my stained glass hobby more enjoyable.

Oh brilliant, what a great tip Jim, thanks SO much for posting. I’ll have to look into this.

I would strongly suggest that one removes the glued-on pattern pieces immediately after one thinks they are ground properly. Sometimes glass can break or crack but is held together by the glued-on template. Glass can also break in such a way as to have “chips” or undercut areas on the edges, especially with a heavily textured glass or a fractures and streamers type glass. When you remove the glued on backing you can assess the edges of your shape to make sure they are good. You can always number the shape and the corresponding pattern area with a sharpie to keep track of where it belongs.

Good point Janey and one worth remembering. Thanks for taking the time to comment, I appreciate it. Numbering is good! Especially when you start making really complex pieces. It can become a nightmare otherwise.

Thank you so much I enjoyed the classes.I did learn a lot thanks.

That’s good to know Kathy, thanks for commenting 🙂

Hello, Im new to this whole glass thing my first project was a frog, what a nightmare… so im starting with a simple big peice pic this time …Your pic and tips were very helpful…Is it true you shouldnt cut the line more then once with the wheeel.. because its not as easy as it looks i found out so i would score it a few times..lol not knowing…boy what a mess 2 hrs and i got one piece that was really not that good…poor frog..he didnt make it….lol

Wish me luck, thanks again for your helpful 3 ways to cut..

You’re welcome Kimberley 🙂 Yes, that can hurt your cutter wheel, going along the same line more than once. Ouch!

Thanks Milly. thanks to the HUB for telling me to go to your site for the saw. I had an idea that I would still be doing the hand cutting otherwise I’ll get very rusty with my cutting. I’ve gotten better the past months being here in lock down due to the virus. I should have asked before getting the saw, but I know it will come in handy with some of the cuts that have driven me crazy. Love every bit of advice I read from you Thank you so much for doing this. Cheers and stay safe and healthy. Nancy

You’re very welcome Nancy, it’s kind of you to say so. I’m glad that lockdown has had some positive effects at least!

There is another way to do it that I us. I trace the piece of the pattern that i want to cut using tracing paper. I then find the are of glass I want to use and put a piece of carbon paper down and retrace the pattern I have on tracing paper on to the glass. You can use carbon paper from any office store and I use seewing carbon paper for my dark colors. Works great for me.

This works too and is a good example of what I always say: ‘try everything and see what works best for you’.

It’s a great tip Lisa, thanks for sharing it.

Thank you for that I have never thought of it

You’re welcome Karen 🙂

Your cutting directions are so great & detailed, it’s as if I was right there watching you! However, I am just starting to use glass, not foil/soldering but in doing glass mosaics. All I have done is taken a class on “glass on glass” mosaics. Unfortunately, I did not know the basics regarding cutting etc. My 1st project is truly the work of a beginner, LOL

Are the cutting techniques basically the same when using glass for mosaics? What is the best glue & type of grout to use?

I appreciate any advice, tips & input you have on doing glass mosaics

Thanks for your wonderful online instructions!

Mary Ann Weisong

Vancouver, Wa

Hi Mary Ann,

Yes, the glass cutting part is exactly the same for mosaics.

I have a page here with instructions for glass on glass work. It’s not written by me as it’s not my area of expertise. I’m too addicted to stained glass! Hopefully it will help you though:

https://everythingstainedglass.com/glass-on-glass-mosaic

Don’t be disheartened about your cutting – you ARE a beginner with it and it takes time to find your feet. Keep at it!

Silicon, but not hot silicon!

Silicon Is a very good adhesive on almost all material. But glass on glass you can use white glue (here in Mexico students use this kind of glue) so when it’s dry its transparent

Thanks for your comment Hector.

For glass on glass I use a UV glue from Loctite AA 349. It’s expensive but a little goes a long way. I don’t use a UV light but in the direct sunlight which is free (outside in summer and thru a window in winter) it only takes a few minutes to cure/bond. Even opaque glass and other materials like flat polished rocks will cure in minutes to glass.

Thank you Sandra, that’s a very useful tip, much appreciated.