Keeping Safe In Your Studio

Ideal Environment, Equipment & Clothing

One of the most important safety considerations is keeping your equipment in good working order. Follow manufacturer’s instructions and make regular safety checks.

I can’t talk about maintenance without mentioning soldering irons.

So many people think that their precious iron looks after itself, week in, week out.

Not so.

By following this simple regime, you’ll be reassured AND you’ll see your soldering improve alongside your iron’s performance.

- Have a good light source. If you can see well, safety follows.

- Work on a sturdy table, at roughly waist height. Make sure it’s not wobbly or unstable.

- A rubber-backed carpet under your work area is a good idea if you don’t have your own fixed workspace. This stops glass from spreading into your home. Always good!

- Use a separate sturdy bin for glass waste, and dispose of it separately.

- Having water nearby helps keep things clean and dust-free.

A basic first aid kit is a good idea, containing:

antiseptic, band aid, gauze pads, a couple of larger butterfly-style bandages. A pair of tweezers for removing the occasional splinter. Eye wash.

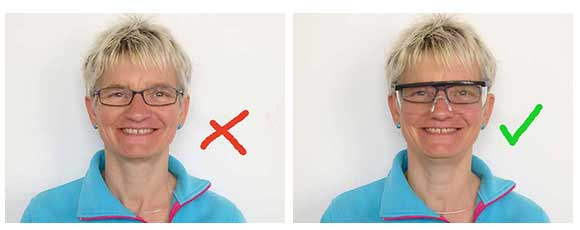

- Wear safety glasses. This prevents you being hit by small glass fragments, hot flux and other such delights 🙂

- Wear safety glasses over prescription spectacles. Double the protection!

- Wear a dust mask if there is any risk of dust being created.

- An apron is a good idea. Or old clothing you keep exclusively for glasswork. This helps keep glass from sneaking into your home environment.

- Wash these glass clothes separately.

- Wear closed shoes to protect your tender toes from hot solder and sharp glass!

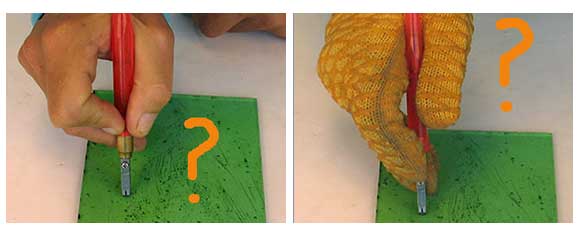

What about gloves?

Some people advise wearing gloves for cutting, but they can make you less sensitive and responsive to the glass. I prefer not to wear gloves for cutting and grozing.

If it makes you feel more confident, find a pair that fit snugly and are rubberised (see photo) to prevent the glass slipping.

Cutting

Safe Working Practices

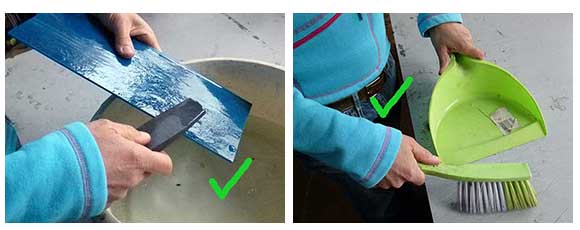

Dust can be a problem if you’re grinding or making the edges safe with a carborundum stone. Use water to dampen the stone and prevent the particles from becoming airborne.

Small cuts are the most common problem. Clean and cover cuts and scrapes immediately with adhesive bandage.

Shards and specks of glass are more likely to cause problems than the bigger pieces you can see more easily. Never wipe shards up with your bare hands! Keep your work surface clear of shards by brushing regularly with a dustpan and bench brush.

Keep a pair of tweezers handy, to remove small splinters (very rare!)

Clean your work area with a damp cloth after each session to prevent glass dust from becoming airborne. This is more effective than brushing or vacuuming.

Wash your hands, arms and face thoroughly after each session.

Handling Glass

Try to handle glass with ‘soft’ hands. Imagine picking up a small baby hedgehog. If you move slowly and handle it gently, you’re unlikely to hurt it, or it you.

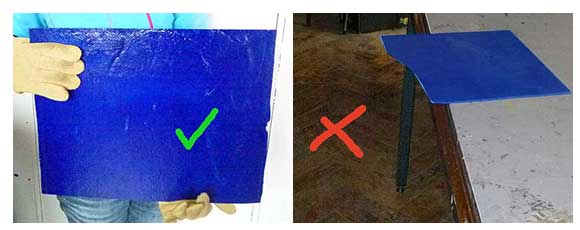

When holding sheets, hold them in a vertical position, one hand below, the other on the side. Use protective gloves if you start carrying larger sheets.

Vertical is best for storing glass, too. It’s always vulnerable when horizontal.

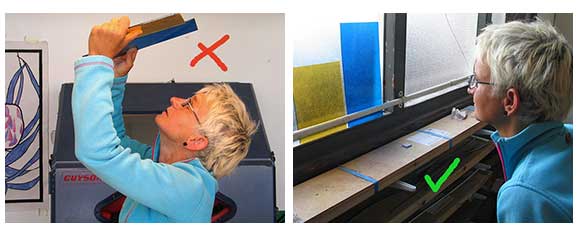

Don’t hold glass above your head, place it on on window sill to look at instead.

If you drop any glass, tempting as it is, never try and catch it! Just move out of the way quickly.

Soldering

Safe Working Practices

- Don’t solder if pregnant or nursing a baby

- Tie long hair back

- Cover any cuts or grazes before soldering

- Concentrate at all times, and look before you pick up a hot soldering iron!

- Take care when you turn projects over. Solder retains its heat so give it time to cool before touching.

- Don’t overdo the flux, it causes more fumes and can cause splattering of hot solder

- Solder on a heat/fire-resistant surface (eg Homasote or similar)

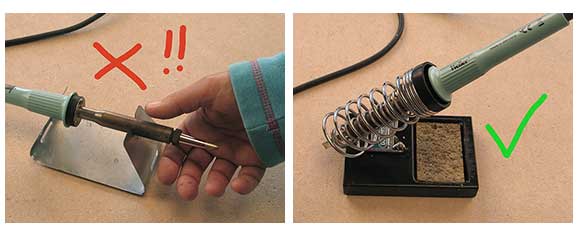

- Never leave a hot soldering iron unattended

- Use a soldering iron stand to hold your iron in between soldering. Never rest the hot iron on work surfaces

- Always check when you place your hot iron in the stand that the wire isn’t anywhere near the hot tip. You don’t want to melt it.

Ventilation And Fumes

When the flux is burning off it is best to avoid breathing the fumes in.

These fumes can be largely avoided by making sure you have adequate ventilation:

- Avoid soldering in tight, airless spaces

- Solder near an open window. If possible, two windows are best for moving air, or use a fan.

- Buy a dedicated fume extractor from a stained glass supply store

- If ventilation is a concern, wear mask or respirator with filters for screening out vapours

- When soldering, bend away from the fumes so that you inhale as little as possible

Read and adhere to manufacturers’ labels on flux and solder products for additional safety information.

What You Can & Can’t Do

Much as you love them, don’t allow pets into your work area

Don’t let children into your work space alone. They must have adult supervision at all times when working with stained glass materials and tools

Sadly, you can’t eat, drink or smoke in your workspace when handling solder and glass. You can listen to music, though.

Make sure you keep your hands away from your mouth and eyes when working with solder and glass.

Keep Safe And Enjoy Yourself

Keep it neat! Tidy workers don’t get burnt. Besides, it’s soothing to work in a pleasant environment.

Be alert! Don’t work when you’re tired, hungry or otherwise distracted.

Keep calm! Rushing will prevent you working safely. It’s part of the craft of stained glass to take your time and enjoy each step.

I am donating Christmas stars, snowflakes, etc. to my church to sell. Need there be any warning that solder is present? You feel a little silly warning not to lick them, then have lunch. The info on selling your work makes no mention so I assume it’s not an issue. Just want to be sure.

Glad you are planning to cut back and smell more roses. You are and have been an encouragement, incredibly available, willing to answer any bizarre questions, and an all around good egg. Thanks so much.

I would warn people, just to cover yourself. No harm and it might help a few that may do just that 😉

Thanks for your kind words about my teacher work, I appreciate that.

Hi Milly

After burning 2 fingers and a thumb, I grabbed the solder iron over the bottom of the handle ( not paying attention) , I decided I needed to make a guard.

I had a pliable plastic disc from the pot of solder. I cut out a circle from the middle (diameter of top of grip) and a cut from the outside to the middle.. The cut allows for the disc to be twisted slightly to get over grip. I then secured the cut with good old black gaffer tape.

It works perfectly, protected now, no more burnt fingers and no cost involved.

Thanks so much for taking the time to tell us of your great solution, Vernice. I’m sorry you had such a painful experience to deal with beforehand. Ouch, poor you. You’ve helped others avoid similar, thanks.

Hello Milly,

Such good tips! I have one for safety. I place my soldering iron in its designated holder and then I place the holder into a cast iron corn bread pan. It is the size of a pie plate and I never worry about burning myself or my work table. I throw my small pieces of solder into the pan and pick them up for small fixes or for my hanging tiny D-rings I use to solder for chain hanging. Stay well! Deborah from Maine.

Wow Deborah, I can see that working very well. Everything both safe AND neat and tidy. Genius. Thank you 🙂

Milly,

I have a small amount of used patina. How do I dispose of it safely?

Thank you

I don’t know where you are but in the UK you can take used materials such as patina to the recycling centre, where they dispose of it. Good question, thanks Sharon.

Thank you Milly,

I am currently designing my new workspace. I have made mistakes in the past in my workspace choices and do not plan to repeat them. I loved the came and glass storage suggestions and will incorporate them into my workshop. What design suggestions might you have for the work bench for cutting glass and soldering? Can they be one in the same, or two separate stations. I always worked on a old Pyrex stove top for cutting and soldering which isn’t ideal but it is easy to clean. Do I need a light table? Can I build my own light table? I’d love to see some examples of the perfect work station from you and your readers.

I have a page on workshop inspiration here Di: https://everythingstainedglass.com/stained-glass-studio-spaces

Yes you can use workbench for cutting and soldering. You can put a piece of carpet (not a hairy one!) or lino down for cutting and clear and remove it for soldering.

I hope this helps.

Great tips! Thanks

Dale

You’re most welcome Dale 🙂

Thank you for sharing. It’s always good to go back and read it all again. Love it

Ha! Glad you liked it Kathy… now, where was that wine and chocolate 😉

I see so many people on Facebook that solder stained glass in their house. I’ve tried and tried to talk myself into this but feel its not safe. I would really like to know your opinion on this. I feel I can trust your judgment.

It’s a good question Melinda. The answer depends on what you feel happy with. If you have a spare room it can be set up with a fume extractor, open windows, minimal soft furnishings. Basically made as safe as possible for working with glass, solder and all the rest of it!

If you don’t have a spare room it’s a bit more difficult to separate out the dangers from your daily living. I wouldn’t solder in my living room, personally. I hope that helps.

I live where it get below 32° at times and it’s to cold to work in the garage. I have a spare room off my dinning room with a window and sliding door, plus french doors to rest of house, is it’s safe to move my work into the house during winter? I dont work with lead came yet only foil.

Soldering fumes and breathing the chemicals are the main risk Melinda. If you don’t have a fume extraction in your garage then there won’t be much difference between that and working inside. You can use extractor fans to blow the fumes away from your face (don’t face it directly on your work while soldering as it cools the solder down too quickly).

Portable extractors aren’t too pricey. This Edsyn is a good one. You can move it with you back to the garage when it’s warm enough!

I hope that helps.

Milly,

I just saw your “don’t do” photo while working in your studio!

You crack me up!!!! I’m still laughing at your photo!

I guess I’m gonna have to give up all those fun things while working in my “she shed”!!!! I have a she shed, not a studio !!!

A safety tip…don’t wear flip flops for shoes!

Take care , Judith

Ha! I’m glad you enjoyed the photo as much as I enjoyed setting it up. Flip flops are a definite no-no, thanks for that!

Sadly, I picked up the business end of a hot soldering iron. Do NOT do that. Something you only do once.

Oh no that’s awful Susan. I once had a student who did that; she had to go home on the bus with a container of cold water to keep dipping her hand in it. I hope it recovers soon.

Thank you for sharing these tips! I do have a question though.

Should I use gloves when handling lead solder and lead came?

Thank you Iveta

Latex gloves are recommended for lead came work, Iveta, yes. I have a health and safety page here if you want other tips on this. I recommend reading manufacturer’s instructions for each product. Very good question, thanks. Safety should always be kept at the top of your mind.

What about gloves for soldering? To protect from absorbing the fumes?

Thanks for the extra tip Mike. You can never be too safe I say 🙂