Stained Glass Painting Answers

Kiln Firing Program For Stained Glass

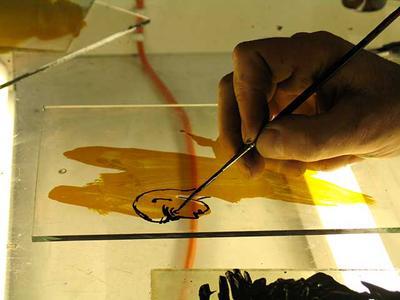

Green Man Painting

I just bought a new glass kiln. All of the pre-programmed firing schedules are for fused or slumped glass and seem very slow. What is a good kiln firing schedule for standard matte (Reusche) painting. I want to fire it to 1250F/675C degrees. And do you need a hold/soak time? I don’t remember using one.

Milly’s reply:

If you’re just firing paint you can go up far quicker than if you’re fusing or slumping glass.

You can go as fast as 930F/500C degrees per hour, but you have to be careful about thermal shock. I would personally not fire quicker than 570F/300C degrees per hour, but I’m never in that much of a hurry!

For Reusche paint I fire at 1200F/650C, soak for just 5 minutes and then OFF. If I fired to 1250F/675C I wouldn’t soak it at top temperature. I do anneal larger pieces of painted glass.

Printing With Heraeus Paint

Colorful glass samples

I recently learnt how to print onto glass using Heraeus paint in powder form which I then mix with a medium. I capped the tile with 3mm Tekta and after firing it resulted in lots of little bubbles which created a lumpy look to the surface of the tile which I do not like at all. Any suggestions on how to avoid these bubbles? My tile was 20 by 20cm

I read somewhere on your site that you pre-fire enamels before capping. Do you think I should do the same with the enamels I use for printing?

Also when you fire many layers to get better colour density, what temp do you fire each layer at? Robyn

Milly’s reply:

Thanks for your questions Robyn. I’ll try and answer them all!

I would pre-fire enamels I was going on to fuse, yes. The same applies whether or not the enamels are printed or painted on. Depending on the enamel, you can fire low firing enamels from 1020F/550C to 1255F/680C top temperature. You can soak from 5-20mins depending on your kiln. For Heraeus low-firing transparent enamels I would fire at 1200F/650C degrees and soak for 5mins.

The bubbles could be occuring because the medium doesn’t have a chance to carbonise if you don’t pre-fire, and/or because you’re putting the textured side of the Tekta facing downwards, allowing pockets of air to trap during the fusing process = bubbles.

I fire Heraeus at 1020F/550C and soak for 10mins if I know I’m going to fire another layer of colour on top. For the final firing I go up to 1200F/650C degrees and soak for 5mins, to make sure that they go nice and shiny.

Hope that helps.

How To Paint Glass – Matting

Yellow glass with swirls

|

|

|

|

Help!

shade and matting? problem with reproduction of soft matting, see photos. is there a special paint mix!! My matting seems to be rougher or bolder, I am looking for a soft fine matting and stippling. by Karl Young

Milly’s reply:

I’m hoping that you mean that you’re trying to replicate the matting above, and not that you’ve done the matting above and it’s not good enough!

For starters, the paint in your photos is brown, which gives softer look than the black paint for glass. Bistre brown Reusche paint is great for this sort of painting job.

You will definitely have to use a badger brush, the bigger the better. Nothing else will do I’m afraid.

I have a series of free Painting On Glass tutorials, which will show you how to paint on glass. There’s one specifically about matting on my Glass Painting Techniques page.

Good luck and I hope you enjoy this process – it can be quite addictive.

Kiln Vent Use When Firing Paints

Kiln with vents

I just bought a glass kiln. Basically all I want to do with it is the painting. I heard that I should use the vents if you’re using lead paints. Is that true and if it is how do you vent the kiln?

Milly’s reply:

This is an important question. When you open your kiln vent you do two things; you give the poisonous fumes a chance to disperse, and you prevent these fumes from causing devitrification (when crystals form on the surface of the glass in an unpleasant ‘cloudy’ fashion).

So when is the right time to use the vent when firing paint? From room temperature up until about 750F/400C degrees. It’s not crucial, but you don’t want to leave the kiln vent open throughout the whole firing cycle because the kiln will cool down too quickly and not give your glass a chance to anneal properly.

It’s best not to be near the kiln during the firing programme, as unpleasant fumes do escape, even if the vents are closed.

Hope that helps, and happy painting!

Help with Duplicating Church Windows Paint technique

I have worked with stained glass as a hobby for about 6 years. I have an opportunity to build two windows for our church, which means duplicating the existing windows.

The painting techniques used appears to be a sponge effect, giving highlight to the center of each rectangle piece of glass. The glass paint is black and appears to be fired on every piece. The glass is red, purple, blue, etc.

These windows were built in 1950. The effect works great.

I have built several large stained glass panels and feel I can do this but I have never seen this done with glass.

Some of the white panels are completely blacked out except for small circles (gives a bead appearance).

Most panels are about 12″ x 4″ varying in colors, so if I could find out how to do this, I could sponge and fire myself.

Any tips or leads I would appreciate. Thanks. Shaun

Milly’s answer:

What a great commission! I too am sure you can do this; you just need access to a kiln and some painting equipment.

If you’ve never done any glass painting – sometimes called enamelling – before, I have lots of information already on this site that might be helpful. To get you started, check out the Painting page for tutorials on everything to do with stained glass painting, from mixing to applying.

You can put the paint on with anything that gives you the effect you’re after. I quite often use sponges, but if this isn’t quite what you want, you could try crumpled up tissue paper or material – play around with a few different things until you’re happy with the effect.

If the windows are up high, try not to get too precious – the viewers will only register the exciting light/dark dynamic that this kind of glass painting with black pigment achieves – they won’t be scrutinizing every mark!

With regards to firing the paint, it’s the simplest kiln firing schedule you can do – 150 degrees C an hour to top temperature – manufacturers will specify, but it’s normally between 550-650 degrees C. Hold – or soak – at this temperature for five minutes and then turn the kiln off. You’ll need to anneal if you have larger pieces, or if your kiln is not very well insulated.

However tempting, don’t open it until it’s reached room temperature! Check out Kiln Firing Schedule to learn more about what your glass is doing during the firing cycle.

I hope this gives you a good start. Let me know if you need any more information, and get the photos on this website when you’re done – I’d love to see them.

Can You Fire Regular Stained Glass?

Mark Angus demonstration

I originally started doing stained glass before kiln work becme popular so of course I have lots of scrap glass. I purchased a kiln hoping to use this glass in the kiln or make frit to use.

I can’t seem to find any answers about the safety of not using special kiln glass.

As I’ve seen wine bottles being used in a kiln I don’t understand the difference in not using stained glass. Does anyone have information about this subject?

Milly’s reply:

Hi Denise, yes, I can help you with this.

You’ll be pleased to know you’re absolutely correct in thinking that you can use your regular stained glass for firing.

All sheet glass has basically the same molecular make-up (give or take manufacturer’s special ingredients!) and can be fired successfully.

I don’t know if you’ve seen my section on painting glass? In it I have a standard firing schedule for paint, which might help you. You can find that particular page here. The firing program is towards the bottom, and there’s also a video that might help you.

You may need to add some annealing time to the firing, depending on the insulation properties of your kiln, and the size of the piece.

Good luck with all your bits of glass!

Firing Paint Quickly in a Kiln

Zebra Glass Painting Designs

I know that I have fired painted glass ramping up from room temp to 1250F/676C degrees in 35 min. I would then turn off the kiln and let it cool down naturally and start venting at 500F/260C degrees. Using this process I could be able to start another layer of painting in about 3hours or less. I realize there is risk of shock but when I am in a time bind sometimes it is a necessity, especially when I need to do 2-3 firings in a work day.

I recently bought a new kiln that has several pre-programmed settings, but there is not one for painting. The fastest ramp time is 300 degrees/hr which seems way too slow. I can create a custom program, so my true question is: What is the fastest, dependable firing schedule that I can use for basic Reusche line work and matting? Mary

Milly’s reply:

You can fire a piece of 3mm glass 40cms X 60cms to 1200F/650C in 15mins in a gas glass kiln, but I wouldn’t go that fast in an electric one. I think you could push it up to 900F/500C degrees an hour without harm, but it does depend on how big your glass pieces are.

If I’m right in assuming the 300 degrees in the pre-programmes are in Fahrenheit (149C), then that is way too low for a simple stained glass paint project. If you’ve got time (!) test out some different sized bits of glass ramping up at 900F/500C degrees an hour just to make sure. If not, just go for it!

Problems with Glass Paint and Patina

I have just begun traditional stained glass painting. I finished and kiln fired several pieces with Reusche paints, copper foiled them together, soldered, and lastly put patina on the lead seams. The patina discolored the painted glass and made the surface gray and noticeable and obvious. What went wrong and how can I avoid this?

Thank-you

Milly’s reply:

This is a brilliant question Joan, thanks. Why? Because it gives me the chance to warn everyone against using black patina with glass paint – the patina contains nitrate acid and will remove the fired paint!

I don’t know why there aren’t any warnings about this on the black patina bottles. Perhaps it’s because the copper foil technique is more commonly used for stained glass work that hasn’t been painted, and so a warning is not deemed necessary? There should be one on there.

I think you were lucky that your painted work didn’t disappear all together, instead of just going gray – Reusche paints are the highest quality so maybe that’s why. I’ve heard of other glass artists losing painted work all together with black patina (Novacan in particular).

You can neutralise the effects of it with baking soda, but it might be too late to rescue your ‘gray’ paint Joan – you really have to do it immediately.

As for the patinas – the copper one doesn’t have this effect on paint, so in future you could try using that – or learn leading and blacken it with graphite!

Sorry I can’t offer a fix, but good luck with your future projects.

What type of Paint should I use?

I plan to do a landscape of painted stained glass and want to paint trees and limbs on it. What kind of paint should I use and does it have to be fired or is there a paint that will last without being fired. For indoor use. Gary

Milly’s reply: The glass paint doesn’t have to be fired, no. Only if you want it to be permanent. There’s other types of what’s called ‘cold paints’ that you can paint your landscape with.

Some of these – the ones you fire in your oven – are more lasting than the ones that don’t get heated at all. It depends what type of longevity you’re after.

Have a read of my Wine Glass Painting page – it goes through the types of paint that need heating in a domestic oven.

If it’s kiln firing and medieval permanence you want, then have a look at my Painting On Glass section.

For the least robust type of paint – I’ve used the Pebeo Vitrail transparent range with success. Just make sure you put enough paint on, and use a circular rather than stroking motion.

Let me know how you get on.

Help Needed For A-level Project

by Hannah

Blue and Yellow Cold Paint

I desperately need to paint my A-level project, but have found that when I try and paint it with the oil based glass paints its spreads very unevenly and doesn’t look good or neat.

I need to paint it by Thursday for it to dry in time, but I’m really not sure what to do. I have the proper paintbrushes there’s 5 different thicknesses but none do the job how I would like it to. Please help!

Milly’s suggestion: Ok, you’ve got to be quick! Thanks for the photo, it really helps me to see what’s going on. It looks like you’re not putting enough paint on in the first place. I’ve used the Pebeo Vitrail range with success – they’re ‘cold’ paints, which means you don’t have to fire them in a glass kiln. There is a transparent range, and they dry fairly quickly.

Put the paint on liberally with quite a stiff small brush, using small circles rather than long brush strokes. You want to cover the area by filling it with paint, rather than smearing it with strokes, if that makes sense?

Try on a small test area first. Good luck, and fingers crossed for your A Level.

Enamel or Glass Paint?

Can you use oil base with a second layer water based for enamels as well as glass paint?

Milly’s reply: Hi Osnat. Yes, you can use this technique for both glass paint and enamels. It is a bit confusing to call them different names, as you can do the same things with them – they’re the same really. Good luck with your project.

Advanced Painting Techniques

I would like to know about more advanced or unconventional painting techniques. I have looked into screen printing and sponging and found very little actual information on process. Would you be able to suggest any other techniques that I may have overlooked?

Milly’s reply: Where to start Mairi…as I’m not quite sure about what types of painting methods you want to know about, I’ll mention a few and a couple of books that you might want to buy to learn more.

Probably the best book on glass painting is ‘The Art of Painting on Glass’ by Albinas Elskus. It’s just been reprinted. He’s really good for a good solid grounding in traditional techniques, and once you’ve grasped those, the world is your oyster.

Have you tried matting (putting a wash of paint over a whole area) and then picking out the paint? See my

Glass Painting Techniques page for detailed instructions.

Have you tried silverstain? That really is quite beautiful. Have a look at my Stain Glass page for an introduction, but Elskus covers that too.

What about printing on glass in various ways? There’s lots of alternatives to screenprinting on glass. Kevin Petrie’s book Glass and Print is fantastic for all sorts of ideas. He prints from etching plates, uses transfers, makes what he calls ‘integrated glass prints’ and uses photography too. It’s a really practical book, with suppliers and detailed instructions all the processes.

Hope that’s enough to get you started. Let me know how you get on.

Painting with Enamel

We’re making a stained glass window of the world and need to paint the land onto the water with enamel. I have some powdered enamel, but I don’t know what kind of medium to use. Also, what temperature do I fire it to? Lance McQuinn

Milly’s reply:

Wow, sounds like a really ambitious project! You can use lots of different mediums. Water is the easiest and gives the liveliest line, but it dries quickly so doesn’t give you much time. Use it with a tiny bit of gum arabic – this will help with the flow and adhesion.

Alternatively you can use Damar varnish-used by oil painters – with distilled turpentine as the thinner. This gives more time, and is easier to paint lines with. Crucially, it allows you to overpaint with a water-based mix once it has dried, which means that you can fire two layers of glass paint at the same time, saving power.

Glass paints and enamels fire at between 550-650 centigrade.

I’d love to see your stained glass world once it’s finished.

Using Unknown Glass Paint?

I was given a number of small jars of paint. It came from the estate of a ceramic and pottery teacher. Some of it is in powder form others are liquids. It is over 10 years old. Can I use this for coloring in some of my stained glass works. How could I test it? Frank

Milly’s reply:

I’ve got lots of similar pots of unknown paint! If they are ceramic colours they’re probably onglazes – they will work on glass but in my experience are opaque and a bit ‘dead’.

To test them for painting, you need to mix them with a bit of water and fire them – all these instructions are in the ‘Painting’ section of my site – and evaluate the results.

Do think about whether it’s worth it for you – you’ll have to test everything and if you like it, you probably won’t be able to purchase any more. It may be better to start from scratch with some dedicated paint, with manufacturer’s instructions. Good luck.

Stencilling And Painting Glass Vases

I want to stencil and paint on a clear glass vase. The stencil is a combo of words and a graphic in gold or etched with a gold coloring. The rest of the glass I want to paint blue. I was thinking about liquid leading to outline the stencil to keep the colors from blending. My question is can this be done successfully? Please tell me how. Does etching cream come in colors or can something be added to it to get color? Thanks!

Milly’s suggestion: Thanks for your question Lorraine. If you let one colour dry before adding the second colour, it shouldn’t blend together. The liquid lead is a good idea for aesthetics, to create a division between the graphic and the rest of the glass.

I’m wondering how nice painting the whole of the glass blue will look – not in terms of the colour, but the fact that it’s quite hard to get the cold paint to apply smoothly.

Etching creme doesn’t colour the glass at all, it just eats into the top surface, making it opaque white. As it disturbs the surface, it makes a very good base for the cold paint. You could etch the vase first, then apply the colour.

Try practicing on cheap window (float) glass first. Have fun!

Where can I buy glass enamels?

Great website! For my new projects I’m going to try my hand at glass enamels. I am using a LOT of plate glass (coe 82+-) and understand I need to buy enamel with the same COE. Where can I buy enamel with COE 82? Paula

Milly’s reply: The compatibility issue is a real one if you are using float. Float manufacturers aren’t interested in us lot and our art glass! They just want to produce glass that tempers well. So… test everything is my mantra. And write everything down… I can guarantee you won’t remember in two years’ time when you want to use it again!

You don’t say if you want transparent or opaque enamels, or whether you’re fusing with it or only need low firing (up to 650 C)? The best for opaque are Ferro. They’ll be compatible with float as they are very strong colours, and therefore don’t need to be put on thickly. They fire at fusing temps, so will withstand hotter (820 C) conditions. If I’m fusing with low firing enamels, I often fire first at 550C, and then cap with clear to ‘protect’ the enamel.

Transparent colours. Heraeus H31 range is the best one I’ve tried, and I’ve had no trouble with incompatibility with float. Again, I don’t use it thickly, as it can craze. I prefer to repeatedly fire the glass with thin layers of enamel to achieve the density of colour I need.

Thompsons enamels are different. They are simply ground coloured glass. They are problematic with float. Enamel colours are a mix of a base clear frit with metal oxides to determine the colour. These are what you need, not the powdered glass (Thompsons) type.

Good luck, I hope your enthusiasm continues!

Painting on sandblasted Glass

If I do glass painting on frosted or sandblasted glass, will there still be a tin residue that I need to avoid?

Thanks! Laurinda

Milly’s reply: Thanks for your question Laurinda. The good news is that the answer is ‘no’, the sandblasting removes the all-but-invisible coating on the tinned side, so you won’t have to bother with trying to identify it in this case. Anything that makes painting easier is good in my book!

Firing Two Layers Of Paint

I loved your site. I’ve been working with glass since 1982. Another way to get more than one layer of glass paint on before firing is to use slightly heavier gum arabic and water on one layer and grain alcohol and NO gum arabic on the second. The second coat comes off very easily, so be careful. This way you can put on two coats of shading before firing.Leigh

Milly’s reply:

Thanks for this, Leigh. It’s really helpful. I’ve never used gum arabic and alcohol as a way of combining firings before – good idea!

I have mixed the first layer of glass paint with Damar varnish and distilled turpentine, let it dry before adding another blended coat with a badger – this time using paint mixed with water. That avoids a second firing too. Any more painting tips out there?

Is it OK to mix silver stain with vinegar?

For my project I need to stain a piece of glass. Most websites come up with painting on glass, but I just want to do the yellow staining.

I did this at school, but I remember mixing the silver stain with a little vinegar and I think a bit of water. Would you know how to do this? Christine

Milly’s answer:

I’ve only ever mixed silver stain (also called silver nitrate) with water.

The vinegar technique is used to enable you to paint one layer of glass enamel over another, so that you can fire two layers at once – something you don’t need to do when using silver stain.

I do have a silver stain page – have a look at: Stain Glass under the ‘Techniques’ section for more detailed information. Hope that helps.

Enamels for Bullseye Glass

I am experimenting by screen printing onglaze enamels and then firing the glass. Is there any enamels you can recommend that can withstand high firing temperatures and have a CoE for working with Bullseye glass?

Milly’s answer:

This is a very good question, given the complexity of glass compatibility issues.

The good news is that there’s no compatibility issues with onglaze enamels, as long as they are applied thinly. Screenprinting is perfect – you can’t get thinner than that!

To explain further: the term ‘enamel’ is a broad term, and covers two types of glass paint:

1. The type you’re working with, which are a mixture of powdered clear glass and highly coloured oxides (eg Ferro, Heraeus)

2. Powdered frits that are simply crushed coloured glass ground down to powder form. (eg Bullseye, Thompson and Schott Artista)

Because type 1. includes intensely coloured oxides, you don’t need a thick layer to get good results – especially with opaque onglaze enamels – and so, thinly applied, this type of enamel is compatible with any glass.

With regards to temperature, type 1. enamels are either low or high-firing – ask the manufacturer which range to choose from. The high-firing ones are nearly always opaque, although the blues can be transparent if fired thinly enough. I use Ferro – their Sunshine Series is high firing – and Heraeus. Reusche are supposed to manufacture high firing transparents, but I haven’t tried them.

Last thought: transparent enamels contain lead and should be used with care.

I hope that answers your questions.

Painting and Fusing Using Float Glass

I fired a painting project in my kiln made of float glass and a lot of air was trapped between the two layers. The bottom layer was painted. I am not talking about tiny air bubbles but pockets of air that made the surface look and feel like cellulite. What did I do wrong?

Secondly if I now slump this into a mould will the glass with the bubbles break or not?

Thirdly how can I avoid the problem in future?

Another problem I had was that firstly some of the paint cracked while others remained solid (paint was mixed with medium).

Secondly, the red color also discoloured to nearly a black while un-sandwiched test pieces remained bright red. Why is this?by Tessa de Wet

Milly’s reply:

Lots of good questions! You don’t say how big your piece of glass was, but as you’re slumping it, I’ll assume it’s bowl-size… You get bubbles where air gets trapped between two layers. If one of the layers is painted, that will make it easier for air to trap. Did your kiln firing schedule include a bubble squeeze? For float glass, this is about 690C, from 10-30 mins depending on size of glass work.

The bubbles won’t make this crack on refiring, but I would take it up slower, and make your annealing cycle slightly more conservative (ie, slow down, hold longer)

The paint cracks when it’s applied too thickly, regardless of medium. So you probably had some areas where the paint was too thick.

Red is fiendishly tricky. Did you fire the paint at a lower temperature first, and then a higher temperature for the fusing? If so, that’s why it went black. Try taking the glass up slower and test it at the highest temperature before you attempt to fuse. The sandwiching itself can also cause red to behave differently – no space for oxides to burn off etc.

I think I’ve covered all your questions – sometimes you have to do lots of different tests before you achieve what you’re after.

Good luck with your future painting and fusing projects.

This painting starter kit is available on Amazon Peter Mcgrain Deluxe Paint Starter Kit (paid link)

I am new to painting glass. I painted an undercoat and then traced a design, followed by highlighting. After firing, I see that the undercoat is too light and the highlighting doesn’t show up well.

Can I repaint, highlight and fire again? And/or, can I use a glycol wash to darken the image and re-do the highlights?

Yes you can over paint and fire again, no problem. It’s worth remembering that a percentage of the paint fires off during firing, so doing it a bit darker the first time is good practise. Good luck.

Which brand of nitrate stain would you recommend? Thanks in advance

Reusche all the way Leo, if you can get it.

This is a question. I have a considerable amount of Reusche paint, a badger brush and two “Stanley Klopfenstine” kilns that I would like to sell. The kilns were made to Stanley Klopfenstine’s specifications, run on 220 and are very fast. I have never had a problem with breakage. I live in a remote area of New Mexico and need to sell them over the net. Do you have any suggestions about how to go about this?

You could try Craig’s List Dawn, or there are some FB groups that are set up just to sell stained glass ‘stuff’. I hope that helps.

Hi Milly,

I’ve just fired my first attempt at glass painting but have noticed that the paint is not 100% adhered to the glass. If I give it a firm rub or scratch with anything sharp, I can remove the paint.

I used reusche tracing black mixed with a bit of brown, gum Arabic and water and fired in a Paragon SC2 following the schedule on your painting page. Any ideas? Wrong paint mix, temperature, hold etc maybe?

Thanks, jenny.

Mmmm, I’m not sure Jenny. Kilns are weird things, each one is different. The good thing about painting is that you normally do more than one layer so you can easily add some more and either go, say 15C higher or soak for longer.

With a new-to-you kiln I’d always suggest testing to get things working before you put stuff you’re precious about it in.

I hope that helps.

Hi Milly,

I had a Kiln Schedule question. I am firing in a ceramic kiln, Olympic Oval 2527 with a Bartlett V6-FC Controller that is new to me. Are you familiar with this controller? I have an old Ramp-Hold Firing schedule below but I wasn’t clear on how to set that up within this controller? I am uncertain of how many segments to use? Is it just one segment? And next, I’m not sure of Ramp Rate?

Any help will be greatly appreciated. Thank you, Robert

Here is the Controller prompts as I understand them:

V6-CF Ramp-Hold Schedule

1. Asks for how many Segments Total

2. Asks for Ramp Rate (ie: degrees per hour) for Seg 1

3. Temperature for Seg 1

4. Hold Time for Seg 1

5. Ramp Rate for Seg 2 (ie: degrees per hour) for Seg 2

3. Temperature for Seg 2

4. Hold Time for Seg 2…

Old Firing Schedule (It’s been a while)

800 degrees – 2:30hr

1100 – ASAP – soak time:03

980 – ASAP

980 – Soak time:30 – 1:00

400 – 4:00

I don’t know this controller but they’re all pretty much the same in terms of segments. Here’s my page with an example kiln firing schedule with reasons for ramp rates https://everythingstainedglass.com/kiln-firing-schedule-1. I hope this helps. Good luck Robert.

Hi Milly, thank you so much for your support and advice for all us newbies to the glass world. I’m a couple of years into lead work, and just expanded into using a kiln with mixed success. I’m getting the trial and error of fusing, and am pleased with the results from both painting and flooding. But note that the fired glass with flooded paint has developed tiny bubbles in the glass that i’d like to avoid on my next project.

I’m not sure if I should be looking at the temperature, the annealing time, the kiln paper, cleanliness etc etc.

Can you point me in the right direction for my problem.

Kind regards

H

Firing anything between two sheets of glass creates air pockets that have the potential to bubble. Slower ramping up, slower top temperatures and longer soaks gives the gases maximum chance of dissipating, so you could try that approach and see how you get on. Vent the kiln on the way up until about 550-600C to give the gases a chance to evaporate.

I hope that points you in the right direction.

Hello!!

Okay, I’m a real newb to painting glass, so I’ll just tell you what I want to do. I’m going to make a GOG lighthouse on an old window, and want to paint the sky. Do I need special paint, or will craft paint work?

The painting I’m talking about here is special pigments that need a kiln to fire them permanently on to the surface of the glass. ‘Cold’ paints are much simpler and might be what you’re referring to. They’re painted on and left to harden. The paints that are semi-permanent are baked in the oven. Pebeo make a good range.

Good luck, I hope that helps.

I want to fire some Rockingham Stained glass paints. Could you tell me the firing schedule please. Many thanks.

I haven’t used Rockingham paints so can’t help you with this one I’m afraid Rosemary. You could try getting hold of them directly; they’re bound to be able to help. Sorry I can’t help you this time.

I want to fire paint onto a 75mm round 2mm glass. My kiln doesn’t do DPH. I’m very confused about conflicting schedules. Please help.

There’s a firing schedule on this stained glass painting page. Scroll down to point number 6 to find it.

I hope that helps.

I’m doing a church window. Main colors are umber brown and black. The painted back looked at in light looks reddish chalk. Is it the medium and heat? If so how do I replicate this to match effect? What temp and what medium or paint type.

I have a firing schedule under point number 6 on this page about tracing stained glass paint. You can get different colours of pigment, including a one called ‘Red for Flesh’. I hope that helps.