Assembling leaded stained glass is a logical process if you know what you’re doing. These answers to common problems will fill in the gaps and make leading up stained glass easier for you.

Assembling Leaded Stained Glass Diamonds

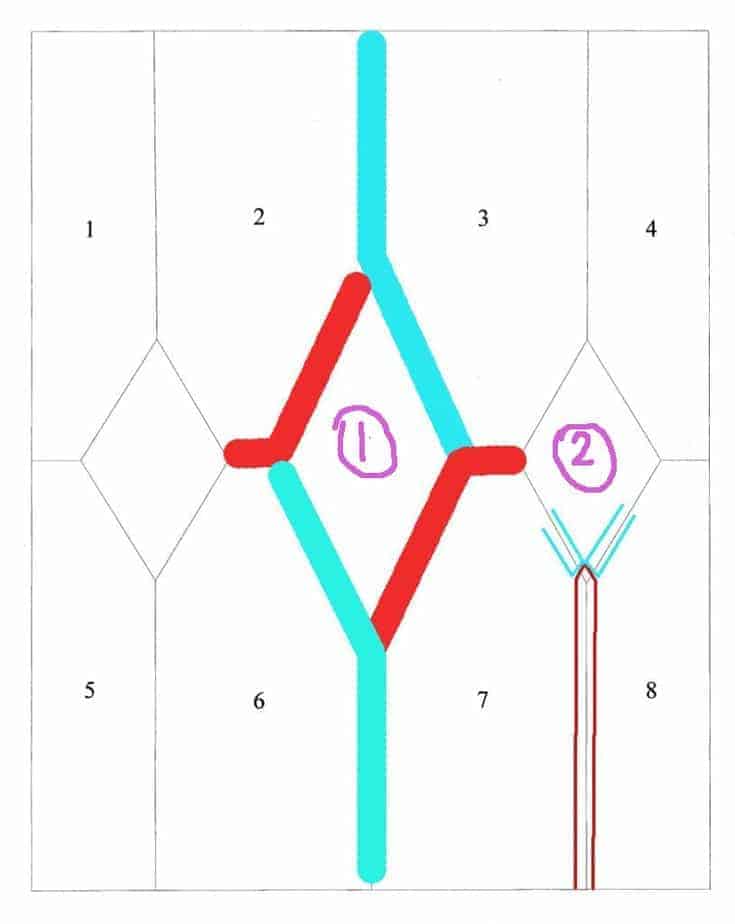

There are a couple of ways to lead up a diamond in stained glass:

- bending the lead came around the diamond

- shaping the end of the lead came to accommodate the ‘V’ shape

You can see these two lead came assembly methods in the diagram below.

#1 is quicker and easier but the angles may be less crisp. You can fix this at the cementing stage by picking out the cement in a defined diamond shape.

#2 is fiddlier and more difficult as you have to cut the lead came very accurately and hold it all in place. It does give a very defined diamond as a result.

Stained Glass Leading – Hobby Came

Question: Do you stretch hobby came like you do standard lead came?

Answer:

Yes you can stretch it gently before using it. Hobby came is normally used for edging small sun catchers and it’s easier to handle if stretched. This is the lead came stretcher I always use (paid link).

Sometimes hobby came needs a few touches of glue around the perimeter along with the solder joints so that it holds to the edge.

Hobby came isn’t for puttying but for small decorative sun catchers. You can put it outside as per normal lead came.

If you’re new to using lead came as a technique I would highly recommend you give it a try. It will add a great deal to your skill set and give you the best of both stained glass worlds – foil and lead. You can even use both together in the same panel!

If you don’t have a local class my Leaded Stained Glass Artistry course has taught many people – even those who have never used lead before – how to make a stained glass panel using lead came. The course is self-paced and online so you can learn this lovely technique even if you are unable to get to a class. You can find out more about it here Leaded Stained Glass Artistry.

Assembling Leaded Stained Glass Windows – Tight or Loose?

Question: I’ve had a couple leading classes from a stained glass teacher who said that the glass should be ‘loose’ in the piece. Loose meaning if you put your fingers on it flat before it is puttied, you should be able to slide the glass back and forth a little inside of its lead came (not loose enough that it falls out). The idea being that you should allow for expansion.

- Should you leave some room for expansion?

- What happens if you have a ‘tight’ fit, ie the glass doesn’t slide at all?

Answer:

#1 Yes, there should be a bit of wiggle room pre-cementing.

A bit of movement gives you room for the cement to squeeze around the glass. This adds stability to your your stained glass panel.

It also gives the panel a bit of flexibility which is needed to cope with different temperatures and weather environments.

You don’t want it to be too loose otherwise it will sag and be structurally weak.

#2 If the glass is totally rigid in the lead there will be no ‘give’ in the glass panel and it will be more likely to hold tension and crack.

Squaring A Stained Glass Panel

Question: I have just built a stained glass panel. The size was to be within the range of 52 X 33 1/2. I find that the size is okay but the window frame is out of square. I have one straight line – the wall but it seems to be wandering away from the wall. The measurements are okay but it is not square. How do I correct this problem?

Answer:

This is a good lesson to learn. Always measure the window frame before making a stained glass window. If it’s out of square make a template and make your pattern from the template.

Traditionally assembling leaded stained glass was done with 1/2″ H came on the outer edges. This gives you a degree of flexibility to shave the flanges of the lead to achieve a good fit if it’s too big.

If there are gaps you can solder additional slithers of lead to the edges. These will be hidden in the installation process.

How Do You Assemble A Glass Circle Project?

Question: How do you lead a circular or oval panel?

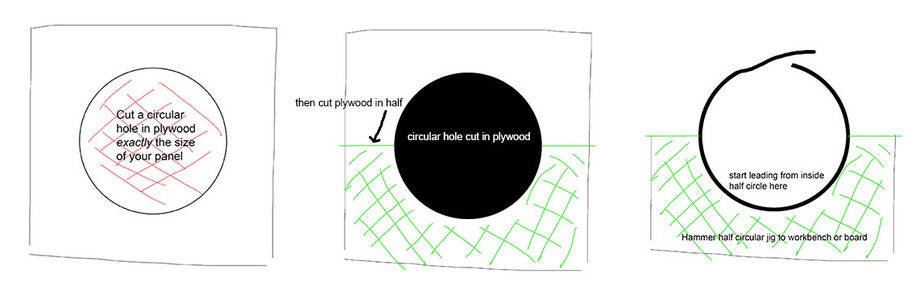

Answer #1: Create a jig out of plywood and assemble the stained glass within it

- Cut a circle out of the middle of a bit of ply wood

- Discard the circle

- Then cut the remaining bit of wood in half and hammer it to your board as a jig. It mustn’t be bigger than half otherwise the glass won’t fit after half way.

- Start assembling inside the arc

- Lead up the circle and use the other half of the ply wood around the top half before soldering

- If you’re foiling, don’t cut the plywood in half, just foil in the middle of it.

- Use U or C framed for the border it’s a free hanging panel. Use wider ones for larger panels to give support and strength. Lead is easier than zinc because you need a came bender to shape the zinc.

Answer #2: Start leading up from the middle and work outwards.

Use lots and lots of horseshoe nails to keep the pieces from moving and on pattern. The speeded up video below shows this method by a master!

If you have some very small, fiddly bits of glass, you can solder them separately before fitting them into the whole, but you have to be very careful that they’re accurately put together, otherwise everything will be pushed out of place.

There are lots of other lead came tutorials here for you

I have a question about attaching a stained glass flower to pretended copper wire. Do I foil then solder the wire to the back of the flower? I want the wire to be the flower stem. Or do I use E600 and glue flower to the wire? Or is there a better method? What I want to do is make several,, maybe 5 flowers with wire stems as a bouquet. Then make a stained glass ribbon 🎀 to go on stems to hold it together. Would this work?

My reply question is why not use real copper wire, so that you can solder directly to the stained glass flower? If you don’t want it copper colour, you could always buy pre-tinned or tin your own wire, as per my video on this page here: https://everythingstainedglass.com/tinning-copper-wire

Sorry if I’ve totally misunderstood the question – it happens frequently, LOL

Its been years since I made stained glass panels. Made one for a cabinet door. It fits perfect but big problem. Some of my pieces of glass are leaving gaps between the glass and the zinc came. Makes it weak and you can see light. 🙁 The dimensions are 10.5″ x 43″. Is there anything I can fill gaps in with I tried putting foil and soldering but that really makes gaps stand out more. Maybe some type of clay? It looks beautiful but the gaps look pitiful. Any suggestions will be appreciated.

If I’m understanding correctly Sandra, you’ve cut the glass too small to fit the zinc? Light will stream in any gaps, causing the eye to focus on them. Gaps that don’t fit into the lead or zinc properly mean the overall panel won’t be robust.

It would be best to repair, recutting the glass at the required size. A pain, but for something that moves like a door it’s more important that it’s strong.

Making my first house sign and it is about 50” long so I have purchased some brass reinforced lead came for the middle. (Zinc on outside and hoping for a blacksmith holder to display.)

QUESTION: Do you stretch reinforced lead came?? I am thinking not but with the length don’t want stretching later.

No, you can’t stretch it as it’s reinforced. Good question Nena, thanks.

I have always used the #2 way to do any kind of angle. I don’t like #1 because it is not as crisp as I’d like it. To me, the way I lead is just as important as the glass cutting to the symmetry of the piece.

I agree Maureen, I like that crisp look too. I agree entirely that the lead lines are of equal importance to the glass. It’s all part of the whole.

if unable to create a jig for a circle or oval for lead came, could we wrap the glass in copper foil then tack the ends of the came to that to get a snug fit? having a hard time with that. thank you.

I’m so sorry Lindsay but I can’t picture what you’re asking. If anyone else can help, please step in!

Do all lead need to be stretched? I use the 6′ straight lead and it’s not kinked. Is stretching necessary for that?

Is stretching also to insure a hanging panel will not start sag or stretch over the years?

There’s a section answering this question on this page Anne: https://everythingstainedglass.com/stained-glass-lead . You’ll have to scroll down to find it under the sub header ‘To Stretch or Not to Stretch Lead Came?’

I hope that helps.

Excellent tutorial! How does one go about shaving lead came? Are there special tools involved? A photo would be helpful. Thanks!

Shave it off with a lead knife Vicki. For small panels you can hold them vertical and shave downwards. Otherwise flat on the bench, shaving one flange and then turn over and shave the other side to match.

Ohhh, ta Milly 🙂 I would have guessed #2, but I didn’t know about #1. Thanks for all the more advanced tips! I always feel like I want to print your emails out and make a book of them ❤️

That’s nice to hear Shandra 🙂 Glad you found the suggestions helpful.

Just thought I’d reiterate accuracy is everything when it comes to leaded or stained glass. It’s not like building a stick framed house.

Spot on Richard, accuracy is key.