Tips for Using Mirrors in Stained Glass

Click the link below to jump to the mirror project section:

Circular Mirror Project

Mirrors can be used very creatively in copper foiled stained glass work. You can use them as a regular looking glass, or incorporate them into lamps or panels. All you have to do differently is make sure you treat the mirror pieces with edge sealant. Here are some useful tips on how to use them and how to avoid mirror discolouration and damaging the backing.

Cutting Mirrors for Stained Glass

- To avoid scratching the silvered back of the mirror place it on a towel or something soft

- Make a score in the same way as you would regular glass. Do this on the top of the clear glass not on the backing. NOTE: Mirrors are often 4mm deep, not 3mm.

It’s very easy to chip the backing when you run the score. To minimise this, do the following:

- Break the mirror immediately after scoring

- Use running pliers from both ends to open the score first

- Intricate curves can also be a problem. Press with your thumbs or the padded handles of your pliers rather than tap the score. If you do decide to tap to open the score do it very gently.

*Before you read any further I want you to know that I receive a small % if you buy through a link on this page. I never recommend anything I haven’t tried and tested out. Just so’s you know! Thanks for your support.

Grinding Mirrors

- Silver backing chips very easily so use the finest grit grinder head you can get – super fine if possible. Alternatively, use an old grinder head which is dulled already. If you use a coarse grit it will chip into the mirror backing

- Keep the backing uppermost to stop any scratching on the grinder bed

- Apply gentle steady pressure as you grind

- Wash and dry the mirror

Before Copper Foiling the Mirror

Have you noticed those black blobs appearing like you get on old glass mirrors? Sometimes this happens a while after completing the piece.

- You need to seal the mirror along the edge where the backing ends to prevent the backing becoming damaged by flux during soldering and to stop these black blobs from creeping in on your piece.

- There are several products you can buy that do this. They are called silver protectors or mirror edge sealant, such as this CSL mirror spray* (paid). Try spraying it on a Qtip to apply it neatly

- Alternatively you can use nail varnish, standard varnish or shellac. These do the job just as well but they’re messier to use and you don’t want it going everywhere.

- Just paint neatly along the edges of the glass, sealing the backing to the glass.

- You can also spray the whole of the back of the mirror with a clear sealant like the acrylic sprays use for cars – or hairspray! You don’t have to do this but it does give added protection to the mirror backing.

*Just so’s you know, if you click and buy through the link within 24 hrs I get a small % from Amazon, (not you!). Thanks in advance but no worries if you have a local store – I’d always support them first 🙂

Copper Foiling Mirror

- Let the sealant dry

- Copper foil over the dried sealant as you would regular glass

Soldering

- When you solder, the backing is less resistant to heat so go faster. Alternatively, use less heat with a cooler iron

- Mirrors can scratch very easily if you use steel wool on your solder. I use an index card to cover the mirror back if I use steel wool.

Circular Mirror Project

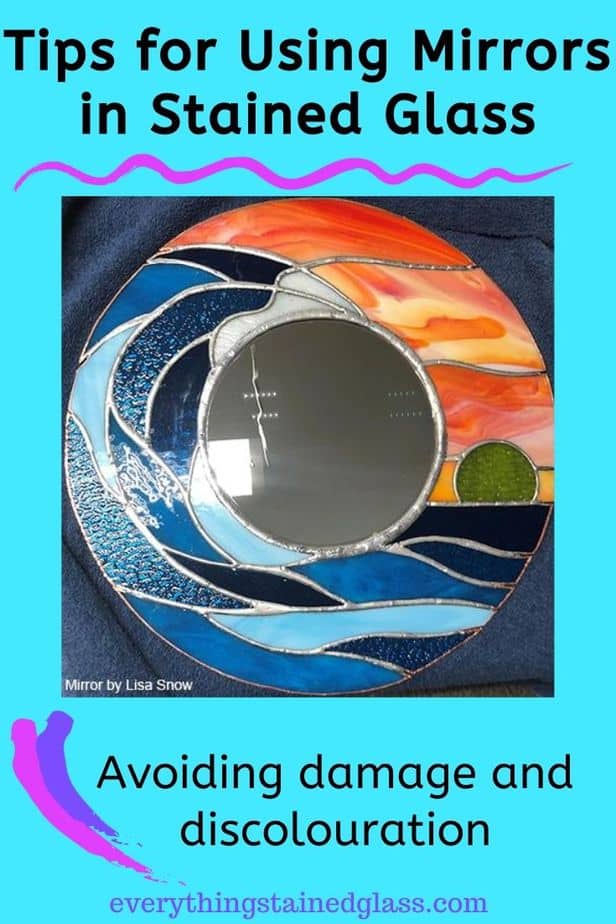

This is a special one for you 🙂 Very generous follower Alan Belisle has shared his wonderful mirror project with us. His is a large and heavy project – it’s 22” circle and weighs over 20 pounds. You can scale this down by adjusting your measurements and materials accordingly. I’ve used Alan’s as an example so that you can work out your own in relation to his.

What You Need

- Embroidery hoop – Alan used a 24” one

- Small nails for holding mirror in place

- 3/4” plywood

- 1/8” Fibreboard

- Aluminium foil

- Fender Washers – Alan used 8 for this large project

- Screw posts

- Glue

- Ceramic tile pieces

- Mirror sealant

- Hooks and wire for hanging

Step 1. Find or design a circular pattern and print it up to size. If you have any points or design elements going right to the edges, you might want to adjust the design so that they’re not chopped off. You can see how here:

Designing Stained Glass Letters and Circles

Step 2. Cut the mirror into a circle and spray paint the backside and edges with sealant to protect the backing.

Step 3. Cut a 22” circle of 3/4” plywood and attach the mirror in the centre with small nails. 3/4” plywood gives plenty of wood depth to nail into. The stained glass will eventually overlap the mirror to help hold it in place

Step 4. Cut a circle of 1/8” fiberboard to fit to the edge of the plywood. Cut out a circle for the mirror, leaving a tiny space around the edge for the small nails to fit between the fibreboard and the mirror.

The fibreboard raises the stained glass and allows it to overlap the mirror when assembled.

Step 5. Cover the fibreboard with aluminium foil for reflectivity.

Step 6. Cut and assemble the stained glass. Alan soldered in 8 fender washers for screw posts.

Step 7. Fasten the stained glass firmly to the plywood with screw posts.

Step 8. Solder glass circles to cover screws.

Step 9. Finish the edges. Alan cut the hoops to size then use the outer part that screws shut to hold the inner part as the glue dried.

Step 10. On top of the edge of the stained glass, glue small ceramic tile pieces from a herringbone flooring tile to finish it off.

Thanks again Alan, for sharing this wonderful project. All the figuring out you’ve done over the months has saved those following you a HUGE amount of time. I’m sure many fantastic mirrors will be created as a result.

What is First Surface Mirror?

A first surface mirror or front surface mirror (also commonly abbreviated FS Mirror or FSM) is a mirror with the reflective surface being above a backing, as opposed to the conventional, second surface mirror with the reflective surface behind a transparent substrate such as glass or acrylic.

We in the stained glass world use FSM for making kaleidescopes.

Questions from Readers

Rust coloured mirror discolouration with copper foil by Deborah

I have tried sealing the mirror pieces after they are cut – on both the backs and the sides – but something is still effecting it.Is the flux leaching into the mirrors in my stained glass pieces? If so, is there a kind that won’t discolour the mirror? Or is it the rinsing that does it? or cutting with oil on the cutter?

Would love some advice!

Milly’s reply:

Hi Deb, thanks for your question and photos – it’s helpful for me to see what’s happening.

These spots are very common – sometimes a rust colour but most commonly black. It’s caused when the the reflective metal coating that backs mirrors becomes tarnished. Whenever mirror is cut, it creates a weak spot where contaminants – such as flux – can creep under the coating.

To give yourself a fighting chance, try to make sure you choose an acid-free flux acid-free flux.

But the secret is sealing the edges tightly with a mirror edge sealant. You can get this from most stained glass suppliers, eg Delphi

Question: How do I clean the sealant off the glass after it is sprayed all around. Will this harm the glass?

Answer:

It’s best to be very careful and not get the sealant on the front of the mirror as it’s hard to get off. Spray it on to a Qtip first to avoid this happening.

Try a non-ammonia cleaner or Isopropyl Alcohol, but be careful at the edges as you don’t want to take it off the bit that’s protecting the back.

Reader’s Mirror Tip

I have used a good quality nail varnish when I’ve run out of sealant. It’s important to spray on both the back and front edges of mirror. Pay particular attention to the places where the backing is chipped, as this is where the corrosives do their nasty work!

I put my mirrors on a brick in a large shallow box, and spray around each edge, turning the box around. Two coats is more effective than one if you can stand it. Do this before leading or copper foiling.

How To Copper Foil Stained Glass

Really beautiful and brilliant projects! Kudos to the artists and to you Milly for again collecting and delivering innovative ideas to us all. I am inspired!

Thanks Linda, that’s kind

Merci pour vos super fiches conseil elles me permettent d améliorer mes créations

Je suis tellement contente qu’ils vous soient utiles pour votre vitrail Badiali, c’est bon à savoir 🙂

Thank you for your great advice sheets, they allow me to improve my creations

I’m so glad you find them helpful for your stained glass Badiali, that’s good to know 🙂

When I use mirror I put painters tape on the glass side to keep the sealant from getting on the front of the mirror. I put a piece of double sided tape on an empty solder spool and tape the mirror tape side down to the spool. This gives me a way to hold it up so I can spray the edges. I put a pair of disposable gloves on and hold the piece up by the spool and spray the sides and back of the the mirror. I let it dry good then peal off the tape and foil as usual.

Always look forward to seeing your tips. Even after doing glass for 20 years there is still more to learn.

Fabulous tip Vicki, thanks so much. Very helpful to us all (proving that we all have something to learn 🙂 )

I put a piece of Contact paper on the back, usually wood grain or clear, and grind it with a fine grit mirror side up. I make sure the foil or lead come over the contact. I try to use as little flux as possible. I have had no trouble in about 40 years.

Fabulous tip Bonnie, thanks so much for taking the time to share it.

Would like to know if there’s any way to remove flux damage from the mirror?

No, I’m afraid there isn’t Joanne. The sealant is the key; make it impenetrable and you’ll be fine for your next project.

Is there any change to suggestions if you are using lead? Thanks

No, I would still protect the edges when leading as the discolouration will creep out beyond the lead into the panel.

Good question, thanks for asking Diane.

Hi Milly. Thank you so much for ALL your texts. . I love them. They are informative & keep me enthused.

I have used Yacht varnish to brush all over the back of my cut mirror pieces. It is simple to use & I’ve had no problems so far. A little more expensive but sure your pieces are worth it.

Sally.

Thank you for this tip Sally, that’s a good one.

And thanks too for your sweet comments about my newsletter 🙂

a very good source of First Surface Mirror

is vintage photocopier

like the xerox 2000 have a big one inside about 3\8 stick and 4×10 inxh a great value

also cannon vintage have some

go to a dealer and asking for recycling mirror inside about 1 or 2 inch by 10 inxh long

the vintage photocopier gestener whit draving move over have x6 pieces inside

a mine of treasorus

Thanks for a fantastic tip Jacques, that’s very helpful for those wanting to source the mirror.

Hi Milly, I look forward to these Sunday emails every week as they are so informative and inspirational especially during this pandemic when I am not going out much at all. Thank-you very much.

So lovely to hear Maryse, thanks for taking the time to write 🙂

I am starting a project with mirrored stained glass and referenced this before cutting. It’s not my first work with mirrors but I couldn’t remember what worked best for me in the past. Now I know on which side to make my cuts and which side up while grinding. I will get that old worn out grinder tip out (knew I was saving it for something, somewhere, sometime). Your tips of placing on a towel and pressing, starting running lines, etc. will be most helpful. Thanks! I have sealed with mirror sealant in the past with success. I sprayed the entire back and edges.

Good timing Annette 🙂 I hope it all worked out for you and thanks for adding your experience about spraying the back.

Milly, your tip on working with mirrors was great, especially for beginners. I have had good success sealing the edges first, then spray painting (saves a lot of time) the entire back of the mirror. This does take time to dry before foiling, ( I wait until the next day) but has worked well for me over the years.

Thanks for your willingness to share.

Thanks for adding your additional information Paul, I appreciate it 🙂

Paul,

What do you use to seal the edges?

And when you spray paint the entire back, what are you using?

Thanks,

Zoe

Hi Milly

I use just plain old “clear nail polish”! Works well; cheap.

Thanks for your tip Sandra, it certainly works if you’re not a messy worker 🙂

This post was perfectly timed. I’m just getting ready to start my first project with a mirror

Yay, spot on. You do know I’m a mind reader, don’t you?!!!

This is a nice article and solves an issue that I have seen and tried to deal in the past. Keep the good work going, I enjoy each week’s notes

Thank you Carlos, much appreciated 🙂