Here’s a page with all my best posts about stained glass tools for you. I thought it’d be helpful to gather them together to provide an easy reference for you.

My personal favourites – with explanations as to why I love them – are in #1 – Recommended Tools.

Have a browse; I’m sure you find a tool you didn’t know about to benefit your stained glass.

Recommended Tools For Stained Glass Making

Favourite Stained Glass Tools & Equipment My tried and trusted stained glass tools have followed me around for years. We share a history like old friends. I thought it could be useful to share a … (read more)

Best Stained Glass Soldering Iron

Top Performing Soldering Iron Your stained glass soldering iron is one of the most expensive items in your kit. And so it should be! It’s a false economy to buy a cheap stained glass soldering … (read more)

Which Stained Glass Saw Do You Recommend?

Stained Glass Saw – Taurus 3 Ring Saw There are 3 main types of stained glass saw; Ring Saws, Band Saws and Wire Saws and they all have slightly different strengths and weaknesses. The Taurus … (read more)

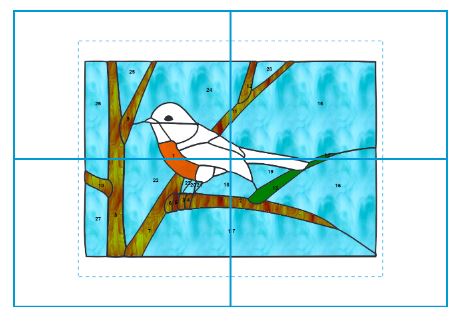

Stained Glass Software – Pattern Resizer Review

Using Pattern Resizer – Stained Glass Software Print Full Size Patterns From Home What can stained glass software do for you? Lots and lots is the short answer! Here are just some of the things … (read more)

Glass Grinder For Accurate Shapes

Best Stained Glass Grinder For Quality And Value The stained glass grinder will soon become your best friend although strictly speaking it is not essential for making stained glass. Click here to jump to Quick … (read more)

Hi Milly

Every Sunday, look forward to receiving your posts.

I have a comment/tip I have used for a few yrs now; has made a big difference in the cleaning of my projects. Picked it up on the net a few yrs ago.

After soldering, of course clean with Kiwk clean; then squeeze on “Mom’s Carnuba Wax” (RED bottle @ Walmart; had to order on net this time as they do not seem to have on the shelf now); let sit 3-4 minutes; using paper towel, wipe until U no longer see black on the towel. Patina, then wipe off with paper towel; using “Never Dull”, shine until U R happy with the shine. Really lots of “hand work”, but, I feel worth it for the shine & the money saved buying the “glass company” same products for shine/cleaning.

That’s a great and useful tip Sandra, thanks so much for posting it. If you have time, could you cut and paste and put it in the Comments Section on this page please? https://everythingstainedglass.com/stained-glass-tutorial

I think that way it’ll reach many more people who are struggling with finishing. Thanks but no worries if not.

I enjoy receiving all your helpful tips Milly. I was wondering if you would consider doing something on ‘knowing when you tools are coming to the end of their lives’ or how to tell when some of you tools or equipment are no longer good? Just an idea . One example may be a spool of solder that I found – the ends were coroded- is this still good and if it is what should you do with it? Thanks

That’s a great idea Alison, thanks. I’ll put it on the list.

As for your solder – try cleaning it with flux and it should be fine. Solder doesn’t have a shelf life, it just gets manky 🙂