Methods For Repairing Broken Stained Glass

Fixing broken stained glass is a necessary evil. With glass as a material breakages are inevitable. You know the scenario; you’re happily soldering away on your latest piece only to turn it and realise there’s a crack in the glass. And you don’t have enough art glass to replace it. This is what happened to one of my readers Ken Keith. He wrote to me asking for suggestions to fix it.

Click the link below to go to fixing broken stained glass with foil:

Foil Repair

Luckily, there is a way to fix this broken stained glass without dismantling your work and driving 75 miles for replacement glass.

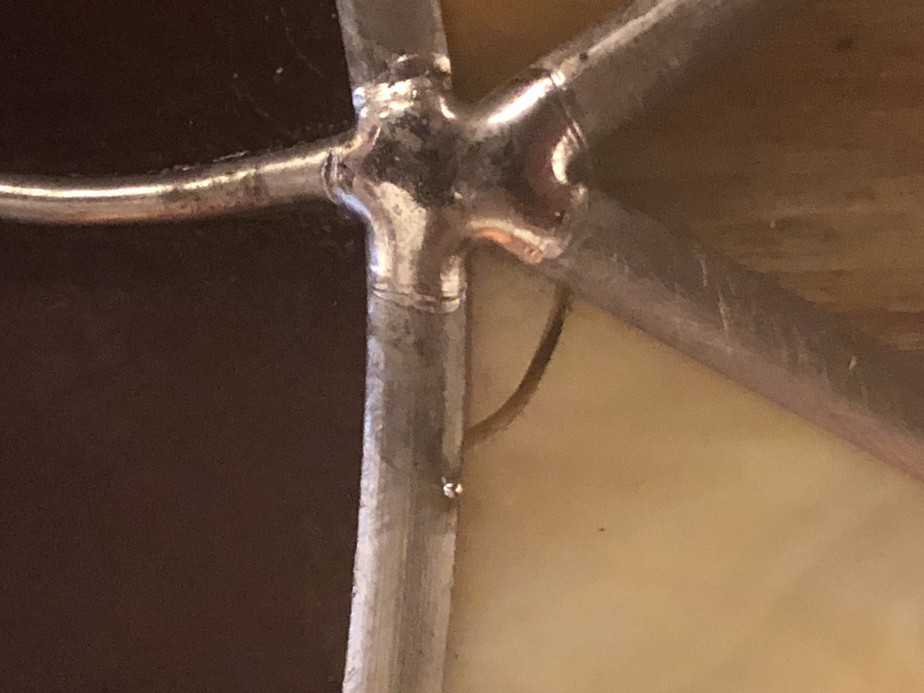

You can see the crack in close up here:

Milly’s Quick Tip For Fixing Broken Stained Glass

Rather than having to undo your work there is a simple fix:

- Find a spare piece of interior lead came longer than the crack

- Cut the top face/flange off a this piece of lead came with either a lead knife, nippers or lead angle cutters

To do this, I use a SHARP lead knife or for this job I particularly like these Lead Angle Cutters ( affiliate link from Amazon) in the US. If you’re in the UK I found a pair here from UK Amazon (affiliate link) – at a very reasonable price considering the price I paid for mine!

- Shape the flange to fit over the crack and trim it to butt up to the adjoining lead

- Solder it at either end to hold it securely in place

- Turn over and repeat on the backside

- Cement, clean and polish as normal

Adjusting The Design

As this is a geometric panel, I suggested add matching ‘false’ leads on the other side of the panel to even the design up visually. You can see how this balances the design below.

If you’re new to using lead came as a technique I would highly recommend you give it a try. It will add a great deal to your skill set and give you the best of both stained glass worlds – foil and lead.

If you don’t have a local class my Leaded Stained Glass Artistry course has taught many people – even those who have never used lead before – how to make a stained glass panel using lead came. The course is self-paced and online so you can learn this lovely technique even if you are unable to get to a class. You can find out more about it here Leaded Stained Glass Artistry.

The client loved the finished stained glass window. I don’t know about you, but I think the additional ‘false’ leads actually ADD to the overall design! They give it a nice bit of detail in the centre.

This is a very good method for lead came when the broken stained glass window doesn’t have to be weather proof. If the window is an external window and DOES need weather proofing, you’ll need to remove the piece of glass and replace I’m afraid.

Fixing Broken Stained Glass – Foil

These instructions are for how to remove and replace a cracked piece of stained glass in a foiled panel. This is a more permanent fix to the one suggested above. This is the stained glass repair you need to do if the panel is going outside or if it’s for a commission.

- Break out the cracked piece. Make multiple criss-cross scores. Tap a small hole with the ball end of your cutter so that you can pull the easy bits of glass out with pliers. Wear goggles of course.

- There might be some stubborn bits left but they’ll come out during the next step.

- Use a hot iron to melt the bulk of the solder off by using gravity and flicking it away from the panel. Be careful and wear gloves.

- Next remove the redundant foil with pliers – needle nose are good. Ease an end of the old foil out, grab it with the pliers, and tease the foil away as you melt the solder. With luck this foil will come off in one piece.

- If you end up disrupting the foil around the surrounding pieces don’t worry, you can remove and replace it. It’s just a bit more work.

- After the solder and foil is removed, clean the area well.

- Now make a pattern for your replacement glass. Slip a piece of paper under the hole in the panel and trace the shape of glass to be replaced.

- Cut, foil and resolder.

That’s it. You now have the skills to fix any broken stained glass. No need to feel that dread when you hear that sickening click ever again 🙂

PIN IT FOR LATER!

More Resources

A more permanent fix for leaded stained glass can be found by going to the amazing Karal’s site. He has a page on how to do leaded repairs to help you.

If you struggle with cutting accurate angles in lead came there’s a page for you here.

I have filled the crack with a adhesive called “e6000” that is clear and some what flexible. Apply the wet adhesive and try to push the adhesive into the crack ,dry in 6 hours.

Thanks Al, I don’t use glue to repair but it’s good to know that it’s an available option.

OnceI went to the Biennale in Stourbridge and someone there was mending glass with some sort of laser device. I was fairly new to glass then and didn’t pay enough attention to what they were doing, but I think it might have been a device/tool which melted the glass on either side so that it formed a whole again. I so wish I had concentrated on what they were doing.. I think there are fairs and glass gatherings where one can take things for repair. Also, doing stained glass isn’t rocket science, it is interesting and fun – so why not tackle mending your glass item by Learning how to do it yourself? Honestly, you’ll love it. Just believe in yourself!!! Also, thank you Milly, always enjoy what you are saying and doing.

That sounds fascinating Annie – very sci-fi! I agree, experimenting is the best way to learn – helping others and being helped by them also moves skills on very quickly.

Hi Milly,

You know, after decades of automotive glass repairing advancements, I’m so surprised that someone hasn’t tried some of the crack repair glue or adhesive used by those guys on some stained glass. I realize there’s a technique to it, and that auto glass is far different from stained, but those guys make the cracks actually disappear! While re-strengthening the glass. I suppose if there were tens of millions of stained glassers someone would have been compelled to invent such a solution just for us by now. I just think we are way past due for such a fix.

I’ve often been asked about this Russ and have come to think the same thing. You could try contacting a manufacturer and getting the ball rolling 🙂

I have a front door that I am very much attached to the leaded glass cut work and it has a few sections that are broken and much of the central leading has cracking and the panel now is concave and needing immediate action. I live in central Mississippi and cannot find anyone who can help me. Does anyone know someone in my area I can contact?

Hi Milly,

I too have had to repair glass, ugh. After breaking out the piece, try using a 1/2 x 3” rectangle cut from an aluminum can. Since the solder won’t stick to the aluminum, you can slide it into the solder joint when heated. Move it along as the next section is heated. It helps to have a second person grab the end of the foil with needle nose pliers and pull as the section is heated.

As always, I enjoy seeing an email from you with another tip.

Robert Wear

This is a great trick Robert, thanks so much for taking the time to share it. I’ve done this and it really does help separate the foils.

I am wanting to fix a significant slumping of a lead came panel. The glass is intact but looks like someone attempted to resolder some joints. I’m not sure if once removed from frame if gravity and maybe heating pad would help straighted slump in panel or what is the best way to straighten. Then it needs putty. Its from an old barrister case.

Thanks for your assistance.

It’s hard to be specific without seeing the piece but it sounds like you need to take the misshapen area apart and re-do with new lead. Good luck.

I have done a similar thing for a piece that was made using copper foil.

I placed copper foil over the crack on both sides and soldered it as if it belonged there — made sure that the copper foil is anchored well to the copper foil on both ends of the foil and soldered on both sides.

Also, if the crack is on a place that might look our of place, place copper foil and solder it making it look symmetrical For example if the crack occurred in the top left corner and the top right corner was of similar design, perform the same things on both corners.

Thanks Milly for all of your tips – I enjoy and benefit from them all.

The perfect solution David, thanks so much for taking the time to share it with everyone. Very useful indeed.

Me gusta mucho el vitreau, pero tengo una dificultad para pegar con la soldadura Estaño 50%, al pegar con la soldadura, ésta no me queda pareja, lisa. ¿que puedo hacer para que quede lisa la soldadura?

Gracias

I have soldering help here for you: https://everythingstainedglass.com/tag/soldering

I hope that helps.

Helll, I love in Brooklyn, NY. I have two pieces of broken glass on two doors in my house. The panels are clear but are in a leaded glass, or came and solder part of the design of the door. Does anyone know who can fix it?

Hello! I am desperately looking for someone that repairs stained glass lamp shades in the Princeton, NJ area. I googles, searched and had no luck.

How would I find someone? Can someone recommend a person or place please?

Thank you for your time!

Wishing all the best – Betty

HI Betty,

I’ve been designing and building stained glass projects for over 40 years. I live in Falmouth Me., next town north of Portland, Me. My Website is http://www.maineglassdesign.com

If interested I’d need a photo of your lamp, and history of your lamp. If it’s made in China, you may want to hold it up to the light for there could be a number of fractures in the glass. I’ve recommended to many people to have a custom lamp made with structure, and quality.

Take a look and let me know, and we can discuss it further.

Thank you,

Carol Coffin………Maine Glass Design

Betty,

There is a very large Stained Glass Supply Store in Wall, NJ. Off of Hwy 34. It’s called Rainbow Art Glass. They may be able to help you find someone.

I live in Florida and have purchased from them. They are a good company.

Donna

Hi Betty, you could call Davidalbertstainedglass . He does repairs he is located in northeast Philadelphia. Byberry Road and Bustleton Avenue.

As always you give the best hints and tips for Everything Stained Glass. 🙂 I look forward to everything you have to offer. 🙂 Thanks kind lady.

Aw Nancy, thank you 🙂

What do you do for small cracks if you’re using solder not came?

I love reading your news – great ideas, suggestions and help!

Thank you!

It depends where the piece is going Debbie; if it’s a commission I’ll repair by recutting and foiling, if not structural and not a commission you can stick tape over the crack on both sides of the glass, solder to the seams at either end and quickly tin the foil.

I am looking for someone who can add steel rods to a wood door with a 2’x7’ Leaded glass insert. I need at least 3 bars attached to door and leaded glass to stableize glass so it won’t crack or bow when door is closed,

Please contact me if you know someone, or are someone, that can do this type of repair.

Thanks

Del

Anyone out there? You don’t say where you are Del, which won’t help people offer their services.

I have a dated mid 17th century window, which my grandmother purchased in 1931. It remained in place for ten years and was then packed away until now. In its removal a number of panels got cracked. The cracks unhappily in the painted parts. Currently, I have the pieces secured w invisible Scotch Tape. I suspect using tape is frowned upon. I have pictures if that helps. Thank you.

Best regards

Stephen

What a shame. Painted work is done in a kiln Stephen so you’ll need to find someone local to you who can do this repair properly, unless you put a false lead over it as I show on this page. It depends if it needs to be weather proof.

I have a few pieces of foiled glass that have broken and I don’t know how to fix them. I’m hoping there is a way to do it although I’ve taken a few apart.

Yes there is Dolores. Make a rubbing template of the broken piece for size reference. Then criss cross score and break out the broken piece. Do this with pliers if you can. And then melt the copper foil off, strips of aluminium can can be inserted in between the old and existing foil as you move around the gap where the broken glass was (solder doesn’t stick to aluminium). Then trace and cut new glass, foil and solder as normal. I hope that helps.

I have a piece I made and cracked a few pieces. Thank you for the above advice as I’ve always been afraid to remove the broken pieces. But how do you get it to actually fit inside again? Is all the lead removed in that space? Thank you for your response.

This is a quick fix Jeanne, just soldering or sticking lead on over the crack. If you were to do a proper repair you’d have to make a call – depending on where the piece is in the panel and the width of the lead – as to whether you fold back the flanges to insert a new piece or systematically take it apart from the closest edge to repair the broken piece.

Genius! My son is a blacksmith – metal artist. His instructor/mentor once told him “it’s not the skill of the craftsman that counts, it’s how well you cover your mistakes”. I was somewhat offended by this at first but over the years I’ve rethought it on occasion. Sometimes, no matter how good you are, how good your product is, you simply need to “fix” something.

That’s so true Erin. I always think stained glass makers have to be engineers and problem solvers as well as artists and makers. We’re a versatile bunch 🙂

Thanks, Milly. I know we all appreciate having your helpful tips coming to us. In the midst of this deadly global pandemic, your emails are reassurance that we can continue to share our love of stained glass together and carry on. Be safe, be well!

Thanks Mary, good to know you’re still stained glassing 🙂 Take good care.

I have used the glue that is used to fix dings in auto windshields. You get one shot at forcing it into the Crack then allow it to cure overnight. You then scrape off the excess glue and if your lucky polish and move on. You can find it in auto parts stores or on line. Worth a shot!

Thanks for this tip Jim; the ‘one shot’ sounds a bit nerve-racking!! Other readers will be happy to have an alternative method, thanks.

Thanks Milly, I just finished a panel and noticed a bubble in the glass that looked like a crack when backlit. I elected to replace the piece rather than be annoyed every time I’d look at it. Your solution is both clever and attractive.

Glad to offer another alternative for you Joyce. I’m with you; I can’t leave anything that isn’t right!

I’ll be looking for the copper foil repair since I don’t use came.

Keep checking back Charlene, I’ll get to it 🙂

Me too, I have worked with came a bit, but I have a few foil pieces that will need repairs, looking forward to your suggestions. Thanks