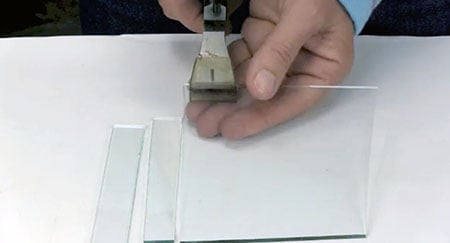

A perfect scoreline makes EVERYTHING easier. But how much pressure should you use when you make a score on the glass?

This is a question that I get asked a LOT, so I decided to make a video with a useful Pressure Test for you to try.

It’s worth remembering that each sheet of glass needs slightly different pressure applied. Some will make the ‘sssssh’ sound and some – like Bullseye opaques for example – don’t make a noise at all.

If you’re having trouble with your cutting accuracy there are lots of tips you can learn to help you get better.

If you don’t have a local class my Conquering Curves course has taught lots of people the skills to cut glass accurately. And not only accurately but without excess effort. How nice is that!

The class is self-paced and online so you can learn these cutting tricks even if you are unable to get to a class. You can find out more about it here: Conquering Curves.

Take the Pressure Test

So it’s a good idea to try this Pressure Test out when your project includes a new type of stained glass that you haven’t cut before. Cut a small piece off and test away! It will give you a feel for how that particular glass responds and how much pressure you need to apply for a perfect scoreline.

In the long run you’ll cut more accurately and waste less glass.

Glass Cutting Checklist

I could blind you with the science of wheel sizes, angles and the mechanics of force but I don’t think that’s what you need. Rather you need a simple cutting checklist to help you along.

- Stand up to cut if you can

This will help you maintain consistent pressure along the whole score. The optimum height for your cutting table is somewhere between your hips and waist - The cutter wheel must be rolling freely

Check before you start scoring - Different brands of glass, different thickness and different colours behave… differently!

Cut off a small piece of any new-to-you glass to see how it behaves. It will save you glass in the long run - Keep your cutter perpendicular to the glass

Don’t lean to the left or to the right as this results in an angled break. A perfect scoreline gives a straight break. - Keep an EVEN pressure throughout the length of the score

If the pressure varies the depth of the fissure will vary and the glass will break randomly instead of along the score line - A score that will result in a good, strong and clean edge is practically invisible from the surface of the glass

You should see it if you look at the glass from an angle

A white line is indicative of a gouge rather than a true fissure. This is the result of pressing too hard and will not give a good break – the edge will be chipped and weak - The depth of the fissure is linked to the speed of the cut. The faster the wheel rolls, the deeper the cut

If you’re speedy, don’t press so hard! If you’re slower, press harder. There’s no ‘right’ and ‘wrong’ – you might cut a straight line quickly and lightly and a difficult shape slowly, pressing harder.

Consistency of pressure is the key - I’m assuming you know not to run along a score twice?

This will gouge or crush the glass, it won’t break cleanly and it will ruin your precious cutter wheel. You can go across a score, just not along it. - It may not be you!

There are – very, VERY occasionally – sheets of glass that simply misbehave. This is normally due to insufficient annealing (cooling down). This happens less and less these days but it’s worth being aware of as a possibility.

Summing Up Cutting Glass Pressure

Author Joseph Farrell put it brilliantly: “The secret of all power is – save your force.”

Get creating that perfect scoreline. Watch the 3 minute video above and take the Pressure Test!

Go here for a list of my other cutting glass tutorials – there are lots of them 🙂

Funny story: I’m new to stained glass, and had been doing ok cutting glass…until my husband bought me a pair of noise cancelling headphones as a gift so I can listen to music while working. Not able to hear made cutting glass so much more difficult! Now I’m thinking about pressure much more as I cut ….your video reinfoces the idea that pressure is more important than sound. Thanks! 😉

That is an interesting story Laura, and one I can fully relate too. Cutting has a lot to do with sounds… such a good point 🙂

I think your checklist is wonderful!! However I have am not understanding how a faster wheel cuts deeper. Could you explain that in more detail please?? Maybe give me some of that science/engineering stuff so I can understand better?? Thanks!

Good question Irene. TBH I’m not a scientist or engineer, I just make a lot of stained glass and read a lot about it 🙂

I think I was poring over the pdf document on this page and it reinforced my experience. See page 8:

https://www.vitroglazings.com/media/10hbno4i/vitro-td-119.pdf

I hope this helps.

When you move quicker you are just scratching the glass which is what you want. You only want to create a weaker spot than everywhere around it so the glass breaks where you want it. When you take longer to cut the line you may be applying more pressure and actually fracturing the glass around the score line. This could result in a fractured cut resulting in more grinding to smooth it or cause the glass to fracture and break in the wrong direction. IMO if you are using muscles to cut glass you are applying too much pressure.

Thank you for the insight on scoring. I have many varied pieces of glass that I purchased at garage sales etc and have had difficulty with some of it. This was very helpful in explaining that different glass will require different pressures. Some breaks very easy and some not so much. I have been using a lot of textured stuff and there is a huge difference, so thank you for explaining.

You’re welcome Barb. It’s nice to know that my tutorial has been of help – thanks for taking the time to let me know 🙂

The tips you sent are great and extremely helpful. Thank you. I haven’t started yet as my brother hasn’t finished with ithe table yet. He doesn’t live close so i am waiting for when he will return. i am glad you are there with these tips.

Let’s hope he’s quick Jane, so that you can get started 🙂 Glad you find the tips helpful.

I’m just trying to learn about stain glass, and having trouble Sodering zinc Ucame. Sodering not sticking to zinc. I appreciate all the help I can get. Thank you

I have a zinc page here Robert: https://everythingstainedglass.com/stain-glass-how-to

Good luck with your stained glass 🙂

One thing i found, was to check and make sure your tools are clean cause just a tiny bit of glass debree will cause your cut not to work.

Yes! Very good point Sandi, thanks for posting and reminding us all 🙂

Thanks so much for these tips Millie, I’m new to copper foiling and have to realise I won’t get everything perfect the first time! It’s great to have you as a reference.

Sandy

That’s a healthy approach Sandy; it’ll help you enjoy the process rather than mithering over what’s not perfect all the time 🙂

Hi Milly. Thank you for all the useful info. It’s wonderful. I have so much trouble cutting thin strips of varying lengths in youghiogheny glass it’s maddening. I even have the silberschnit running pliers but it’s still a roll of the dice that I make a clean cut. Any advice besides what you have graciously given so far ? Thank you

mmm, that glass can be a bit tricky. Have you tried placing it on a towel or softer surface to allow for the unevenness? I’d do that glass freehand, too, so that you can ease your way over the slight lumps and bumps.

And ease the cut open with the pliers the whole way along.

No magic bullet I’m afraid but I hope that helps a bit.

Love the scale tip — that’s super clever, and a helpful thing for me to try out as a newbie! Much appreciate it.

That’s great to hear Fiona, thanks for posting 🙂

How long does a cutting wheel tool last!

If you treat them well – don’t press too hard, maintain them well, don’t go over scores a second time and don’t use them every minute of every day they’ll last years.

If you don’t treat them well it could be a matter of months.

Irregular score lines that don’t cut cleanly are a tell tale sign of a wheel that needs changing.

It’s one of those ‘long as a piece of string’ questions, Robert but I hope that helps some 🙂

Thank you so much for sharing your knowledge and experience. I have found your information very helpful and it reassures me of practices I am doing right and makes me more aware of what I need to work on.

Great to hear Charlie, thank you 🙂

If I’m getting these emails on a regular basis am I to assume that I am signed up or is this another group of information? I just want to make sure but also not duplicate my membership. Thanks, Bud

Yes Bud, you’re signed up and not missing anything 😉

Very good information on pressure when cutting the glass.

Thanks Sandy, glad you found it of help.

Wow, duh….I never thought about pressure. Thanks a million!

I have lots of those ‘aha’ moments Lynn. I’m glad this one helped you.

Hi Milly, I’m your latest member…I need all the help possible…With your help I’m sure I will learn very quick…Tony in Florida

Welcome Tony from Florida 🙂 I hope you get addicted to stained glass and love it like we all do.

Great video. I learned why my edges are not smooth.

Thx

Great to hear Suzanne; once we know what’s not going well we can adjust it 🙂

Wondering how you can tell if your cutter needs to be replaced? What is a good cutter to buy

If the score line is broken at regular intervals it means the cutter head needs replacing. I like the Toyo cutters like this one here. You can replace the heads rather than the whole cutter.

I haven’t looked at the link for all your glass cutting tutorials, but wondered if you have one on cutting textured glass, like ripple and herringbone?

Thank you so much.

Thanks,

Naomi Fron

There’s the obvious – always cut on the smoothest side and a towel under for heavily textured glass. Use a ripple bit on your grinder if you want to foil it after.

I’d recommend a saw for these glasses:

https://everythingstainedglass.com/5-things-stained-glass-saws-well

I hope that helps!

I do cut on the smoother side, but some pieces of glass still have blemishes that want to grab my cutter wheel. Any advice on handling that? Is that also a pressure thing?

Great question Ginger, thanks for asking. I have a video on this page showing exactly how to deal with this:

https://everythingstainedglass.com/rescuing-score-confidence

I hope it helps.

Thank you MIlly, this video on glass cutting pressure is so helpful! What kind of pliers are you using? Thank you ~

They’re cut running pliers Janet – like these ones here.

I’m glad you found the video of help 🙂

Thank you so much for the pressure test tip. Amazing how little pressure you need to break cleanly.

Isn’t it Judy?!! Once you start applying the same method to art glass you’ll start to notice the difference to wastage.

How can one cut diamond glass shapes?

Is there a simple way to do this ??

Using a ruler or a strip cutter is best Ferne. That way you’ll get a nice straight line. If it’s a diamond with a long thin point, use the breaker-grozer pliers to tease the end open so that you don’t snap the point off.

Hi,just signed up to receive your tips & info. I’m new to stained glass but having a bit of trouble with foiling for some reason. Sometimes I Can’t get it perfectly centered so I don’t know if,when I go to solder it,the pieces won’t be attached properly. What am I doing wrong?

You can try using lined paper as a guide for the foil until you get the hang of it. If you’re making a stained glass sun catcher or a panel that has foiled edges, start foiling on the part of the glass shape that is internal; in other words, try to avoid the foil meeting itself on the outside edge of the piece. I hope that helps. Thanks for your question Kaye.

I am so glad I found your site! I took stained glass classes about twenty years ago but never kept at it due to children, many moves and lack of space. Now that I have room and a designated area to work in I have been working on small projects. It has been frustrating because I have pretty much forgotten everything I learned way back when! I know I have been pressing to hard while cutting and will definitely take the pressure test. I have a question about my cutter. I bought a pistol grip thinking it would be easier for me. While I do like it, I have a problem with the cutting oil coming out when I press down to cut a piece. It makes a big, wet mess. Any ideas of what could be causing this?

Oil will leak from cutters, especially these ones. You can try storing it in a jar wheel up but the best solution is to put some oil on a bit of sponge in a jar and dip the cutter in every few cuts. Not fill the cavity with oil at all. That way you have more control of the oil and definitely less mess. I hope that helps.

Welcome back to stained glass Pam 🙂

Older & pasted glaziers who had no access to self feed cutters would keep a shallow tin or glass jar with a saturated felt pad of sewing machine oil which they would dip their cutter before each run.

ps showing my age?

Ha! I hope not; I still do that as I find some of the barrels leak oil. It’s more controllable. Thanks for your thoughts.

(PS I am getting on a bit though LOL)

Great info for a newbie! Thank you! My biggest problem is w imperfections in the glass (pock marks and cuts). The wheels gets stuck or skips and it’s hard to control when it hits one. Am I getting poor quality glass or is this the norm? Any tips for negotiating the glass terrain?

Yes, I have JUST the thing… it’s the tiniest snippet taken from my Stained Glass Made Perfect online course, you can see it here:

It answers your question precisely 🙂

ths for your clear explanation how to cut glass. I m looking forward for your next side.

I’m glad to hear it helped Gwen, thanks 🙂

I am a new glass fuser. I find your tips most useful. Please keep them coming.

Ah… a fuser! We have cutting glass in common so I’m happy to hear you find my ideas useful. Thanks for posting.

Good reminders. And a well done video. Thanks!

Glad you found the video clear. Thanks Mark.

Hi Milly.

I havn’t done glass in 20 yrs and forgot most everything. I’m so thrilled to find you. Thank you for all your help

You’re welcome Susan. I’m sure it will all come back to you quickly; it’s like riding a bike 🙂

Ths. for the good and simple tips. I appreciate them very much.

You’re most welcome Gloria, it’s kind of you to take the time to comment.

Hi Milly

Can you please show us what is the best way to cut a leaf shape?

Thanks, Sam

Hi Sam, I’ve got a slideshow that shows how best to cut a leaf shape. Click here to go to the page and then scroll down to the third slideshow

Thanks Milly, your videos and slideshow are very helpful. I’ ll keep in mind when I’m doing my leaves.

Sam

Yep – I’m guilty of pressing too hard. Now I know why I get those teeny weeny chips along the cut line sometimes . Thank you for the tip.

Hi Dale, glad you’ve isolated a possible problem before it takes hold. These things have a habit of adding up and making stained glass more difficult than it should be.

Hi Milly.

I am relatively new to stained glass work, I have enjoyed your video hints and tips and hope there are more to come. After watching them I am hoping to cut more accurately and not spend so much time grinding. Thanks Milly.

Jenny.

Hi Jenny, thanks for your kind comments. There’s nothing wrong with grinding but it does save time and grinder bits if you can cut neatly and use the grozer pliers. Good luck with the cutting!

Hi Millie,Just to say thanks alot for all your tips. Most useful. Farook

Thanks Farook, I’m happy that you find them useful! Happy glassing to you, Milly

Thank you for this video. I do have trouble with the pressures I apply on different types of glass. It sometimes is to the point that I have to stop because my arm is so tired. I will keep practicing, and making, and enjoying each piece because I am so hooked on this. I am so proud of each piece when I am done. Thank you Millie for your tips.

A stained glass artist in the making,

Martina Brown

Hi Martina, That pride that we get when we keep going and then succeed is the best feeling. You should be proud, it’s not the easiest craft but it is the absolute BEST 🙂

I’m glad the video helps. Hopefully you’ll be able to work out how hard to press for each type of glass… it takes a while to build up experience so this is a good quick guide. Good luck, Milly